|

Central feeding system| RSS

|

|

central feeding system |

|

central feeding system |

What is a central feeding system? |

source:Central feeding system Author:Central feeding system time:2020-07-18 15:01:44 |

|||

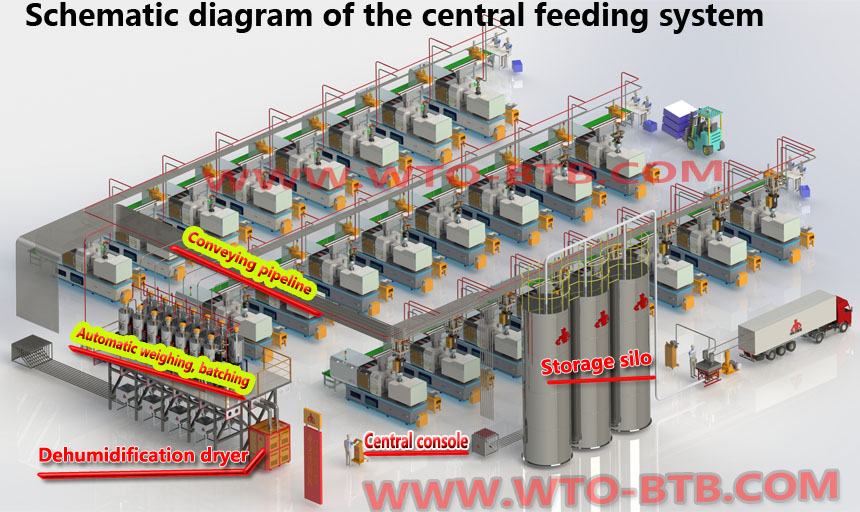

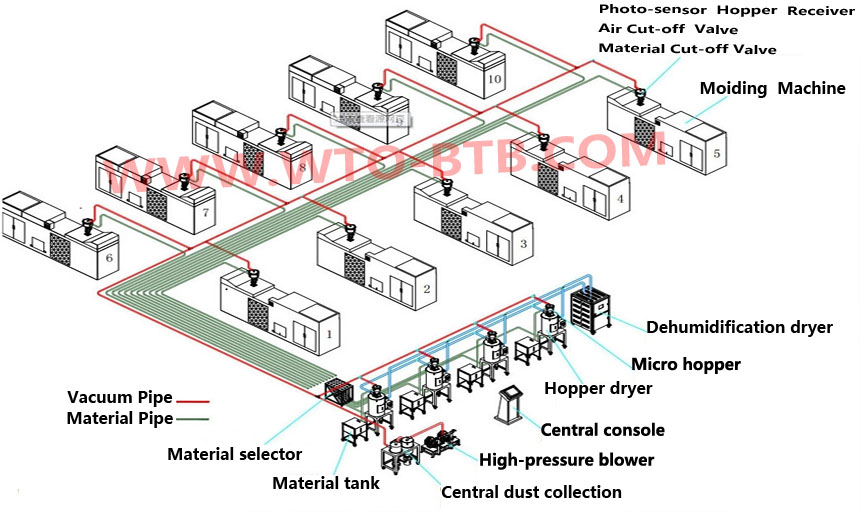

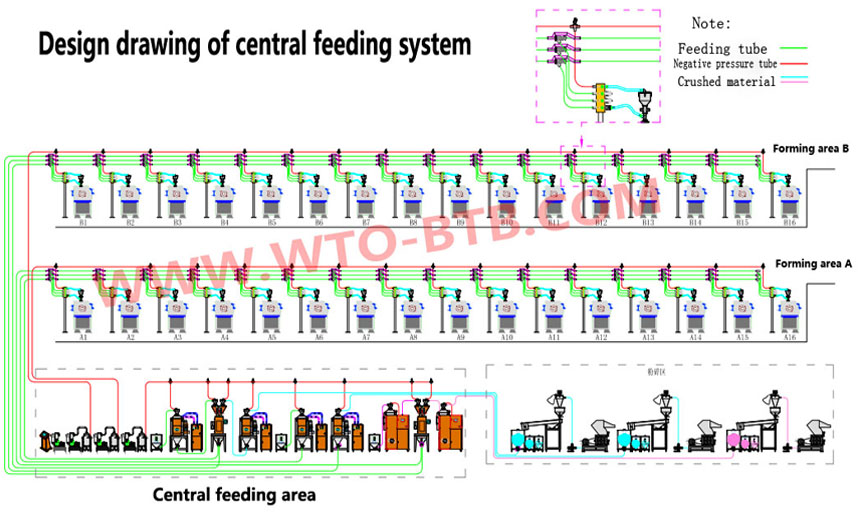

| Central feeding system-also known as automatic feeding system, centralized feeding system and central conveying system. The central feeding system is specially designed for the production of plastic products in the injection molding workshop, which can realize unattended unmanned continuous molding operations. The type of raw material and the combination of materials of multiple colors can be changed as needed to automate the coloring process. The system can fully automatically regenerate and use cold injection materials, can control all feeding equipment, and prevent storage tanks from clogging. It is an automatic system with automatic feeding, automatic dehumidification, automatic drying, automatic feeding, automatic weighing, automatic mixing and automatic dust removal in the plastic workshop. The central feeding system consists of a console, Dehumidification dryer, weighing mixer, suction machine, conveying pipe and other mechanical equipment! By setting up a central monitoring station, it is completely automated. The centralized feeding system adopts microcomputer centralized automatic control to realize the continuous feeding operation of pellets for 24 hours. Multiple small microcomputers respectively control the coloring process of each molding machine,the measurement is accurate, the mixing is uniform, and the color can be flexibly changed to meet the requirements of multiple colors and varieties. According to the output of different molding machines, the feed amount can be flexibly changed. The design of multiple feed pipes can ensure the diversified requirements for the main materials. The system has multiple monitoring and protection functions, safe and reliable. Alias for central feeding system: centralized feeding system, automatic feeding system, etc. Working principle of central feeding system The central feeding system adopts vacuum conveying method to transfer the plastic raw materials from the storage tank to the central dehumidification and drying system through the centralized pipeline system, and then transfer the dried raw materials to each injection molding machine. The central feeding system adopts the design method of "one machine and one tube" to ensure that the entire system is transported with air and prevents moisture from drying. At the same time, the operation of each transmission is stable and no blocking occurs. It is used in conjunction with the central dehumidification and drying system, which can be used to clean the pipeline after dehumidification, drying and circulation to ensure that there is no residual particulate matter in the pipeline. While avoiding the resurgence of raw materials, it also ensures that the raw materials added to the injection molding machine performance. Consistent. Under vacuum negative pressure, the dust in the raw material will be filtered through the dust filtration system, which helps to improve the quality of the molded product. The central feeding system adopts vacuum conveying method to transfer the plastic raw materials from the storage tank to the central dehumidification and drying system through the centralized pipeline system, and then transfer the dried raw materials to each injection molding machine. The central feeding system adopts the design method of "one machine and one tube" to ensure that the entire system is transported with air and prevents moisture from drying. At the same time, the operation of each transmission is stable and no blocking occurs. It is used in conjunction with the central dehumidification and drying system, which can be used to clean the pipeline after dehumidification, drying and circulation to ensure that there is no residual particulate matter in the pipeline. While avoiding the resurgence of raw materials, it also ensures that the raw materials added to the injection molding machine performance. Consistent. Under vacuum negative pressure, the dust in the raw material will be filtered through the dust filtration system, which helps to improve the quality of the molded product.

The composition of the central feeding systemCentral console, cyclone dust collector, high efficiency filter, fan, branch station, drying hopper, dehumidifier, material selection rack, micro-moving hopper, electric eye hopper, air cut-off valve, material cut-off valve.

Design process of central feeding systemRaw materials → storage → metering → drying → conveying → use The central feeding system adopts one machine and one tube, and adopts a sealed circuit design method to ensure the stable operation of the entire system, without the phenomenon of plastic moisture regain and blockage. It is used in conjunction with a central dryer (dehumidifier) system to dry the raw material again with dry air to prevent the plastic from regaining moisture after drying. At the same time, the delivery pipe must be cleaned after each delivery cycle to ensure that there are no residues in the pipe. While avoiding the resurgence of raw materials, it also ensures the consistency of the raw materials added to the injection molding machine. Under the action of vacuum and negative pressure, The central feeding system adopts one machine and one tube, and adopts a sealed circuit design method to ensure the stable operation of the entire system, without the phenomenon of plastic moisture regain and blockage. It is used in conjunction with a central dryer (dehumidifier) system to dry the raw material again with dry air to prevent the plastic from regaining moisture after drying. At the same time, the delivery pipe must be cleaned after each delivery cycle to ensure that there are no residues in the pipe. While avoiding the resurgence of raw materials, it also ensures the consistency of the raw materials added to the injection molding machine. Under the action of vacuum and negative pressure,

Characteristics of the central feeding system1. Efficient: The central feeding system can realize the automatic supply of various raw materials to any injection molding processing equipment in multiple chambers, including the drying processing of raw materials, color matching processing, and the use of recycled materials that are broken in proportion. Automatic control, monitoring, etc., and can meet 24-hour uninterrupted production needs.2. Energy saving: The central feeding system is easy to operate, and only a few people can control the feeding requirements of the entire injection molding plant, thereby reducing a lot of labor costs. Secondly, the raw material belt and corresponding auxiliary equipment beside the injection molding machine are reduced, and the space utilization rate is improved. In addition, due to the centralized power supply method, a lot of independent equipment is correspondingly reduced, electricity is also saved, and maintenance costs are reduced. 3. Personalization: The central feeding system can realize different users, different workshop characteristics and different requirements for the use of raw materials. The optimization program can be designed according to actual needs. 4. the image of a modern factory: the central feed system will minimize the contamination of raw materials and dust in injection molding production, which can maintain a clean production workshop, and the central feed system has a unique centralized dust recovery system, which is more convenient and clean. The environmental protection effect is to meet the standards required for the operation of the 100,000-level clean room, and to reduce noise, and ultimately can realize an unattended automated production workshop and establish a modern factory management image. The functions of the central feeding system components:The functional characteristics of the central console:1. Using PLC and large-size 10.4-inch color man-machine interface touch screen, easy to understand and easy to operate;2. Color-coded written display of various settings, operations and operating states; 3. Equipped with material tube evacuation and cleaning tube, automatic dust removal and dust collection central feeding host A, B alternate automatic switching and manual material selection error prevention function; 4. Added raw material control screen to monitor the raw materials used by each molding machine, suction, insufficient materials and various abnormal phenomena of the central host (motor). The function of the central feeding host:1. The motor design does not stop, avoid frequent start of the motor, causing wear;2. With safety relief valve, when the movement pressure of the host is too large, the safety setting value is overloaded, and the relief valve automatically releases the pressure to protect the motor; 3. The two A and B of the feeding host are alternately placed, and have an automatic switching valve design to ensure the stability of raw material delivery. Features of automatic reversal cyclone dust collector:1. The integrated design of air filter and cyclone dust collector can effectively collect dust under the action of natural centrifugal force;2. Can install high-pressure gas tank, and automatically clean the filter; 3. The dust collector is equipped with an air cut-off valve, which can effectively move the dust in the dust collector without shutting down. Features of the fast feed station (Fenqi Station):The branch station is composed of several branches, and the raw materials of the same branch pipe can be used for the injection molding machine. Each branch has fast head tightness; it can improve system efficiency and make material replacement convenient and fast.Central feeding system maintenance:①, establish maintenance files, record daily operation and maintenance;②, implement a special management responsibility system and independent operation responsibility system; ③Train operators regularly, especially new employees; ④ Regularly check the conveying pipeline, especially the vacuum pipeline and compressed air pipeline for leaks; ⑤ Perform regular maintenance on a single machine in the system; ⑥After cleaning the suction hopper and drying barrel, they must be installed in place; ⑦, regularly clean or replace the central filter; ⑧, regularly clean the dust of the electrical parts of the equipment; The centralized feeding area should improve the ventilation of the equipment. The user performs daily maintenance, monthly maintenance, quarterly maintenance and annual maintenance on the centralized feeding system, which can ensure the normal and stable operation of the system, and timely contact the manufacturer when problems are found. This can ensure long-term normal operation and long service life of the system. Can save maintenance costs. Let the central feeding system play a greater role and benefit. Central feeding system, Automatic feeding system,Centralized feeding system,Central conveying system

|

Central feeding system technology and maintenance |

| Dehumidification dryer | gravimetric blender | plastic granules mixing machine |

|

|

|

| Links: | plastic dryer | Dehumidifying Dryer | gravimetric blender | Central feeding system |

| company name: | Dongguan Machinery Equipment Co., Ltd. |

| Phone/WeChat: | +86-13669807274 | Whatapp: | +86-13669807274 | E-mail: | wto-btb@wto-btb.com |

| Address: | 168 Guangming New Street, Dongcheng District, Dongguan City, Guangdong Province, China |

| Website real name: | Central feeding system | copyright: | Central feeding system |

| industry search: | Central feeding system | Central conveying system | ©2007-2029 @ |