|

Central feeding system| RSS

|

|

central feeding system |

|

central feeding system |

Centralized feeding system design solution |

source:Central feeding system Author:Central feeding system time:2020-08-12 16:14:24 |

|||

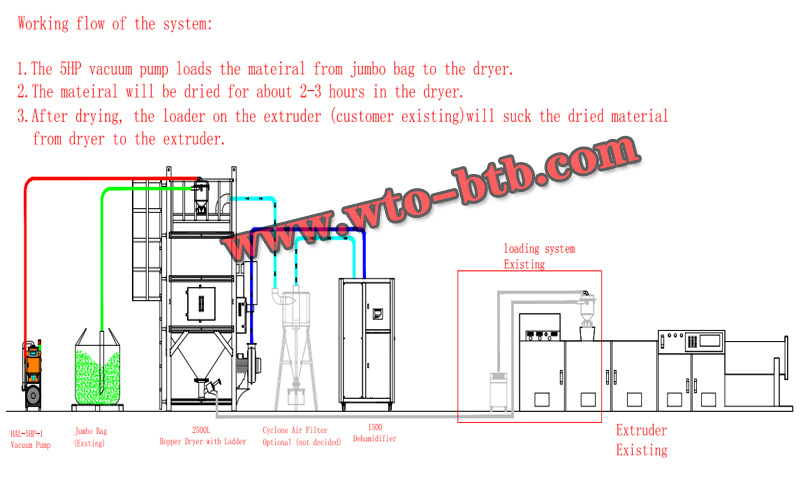

| Design and scheme of centralized automatic feeding system Raw material → storage → measurement → drying → conveying → use  The centralized feeding system adopts one machine and one tube, and the sealed loop design method ensures the stable operation of the entire system, and no plastic regaining or blocking occurs. It is used in conjunction with a central dryer (dehumidifier) system to allow dry air to dry the raw materials again to prevent the re-moisture of the dried plastic. At the same time, the conveying pipe is cleaned after each conveying cycle to ensure that there is no residual material in the pipe. While avoiding the resurgence of raw materials, it also ensures the consistency of raw materials added to the injection molding machine. Under the action of vacuum negative pressure, the original dust in the raw materials is filtered out through the filter (dust collector) system, which is beneficial to improve product quality

|

Important equipment of central feeding system |

| Dehumidification dryer | gravimetric blender | Plastic weighing mixer |

|

|

|

Central feeding system technology and equipment |

| This is the manufacturer of Centralized feeding system design solution https://global.wto-btb.com Information provided |

| ( https://global.wto-btb.com It is a free service platform for global suppliers) |

| Links: | plastic dryer | Dehumidifying Dryer | gravimetric blender | Central feeding system |

| company name: | Dongguan Machinery Equipment Co., Ltd.(东莞市机械设备有限公司) |

| Phone/WeChat: | +86-13669807274 | Whatapp: | +86-13669807274 | E-mail: | wto-btb@wto-btb.com |

| Address: | 168 Guangming New Street, Dongcheng District, Dongguan City, Guangdong Province, China |

| Website real name: | Central feeding system | copyright: | Central feeding system |

| industry search: | Central feeding system | Central conveying system | ©2007-2029 @ |