|

Central feeding system| RSS

|

|

central feeding system |

|

central feeding system |

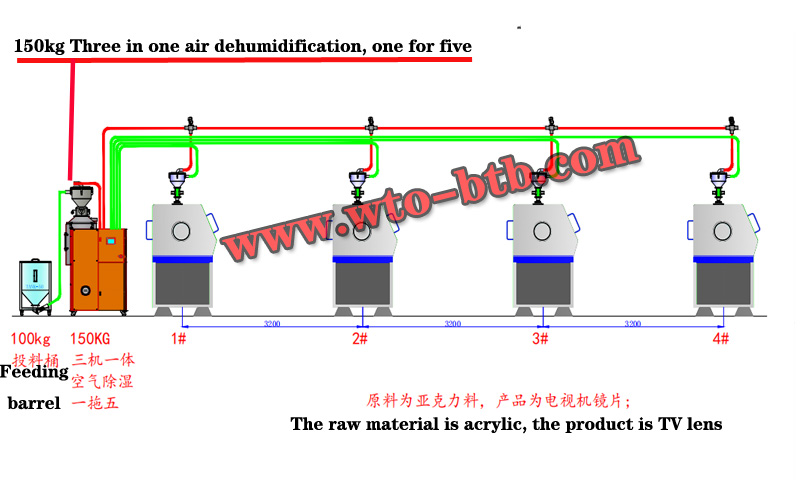

Cost-saving budget central feeding system flow chart |

source:Central feeding system Author:Central feeding system time:2020-08-12 16:11:44 |

|||

| The invention relates to a multi-component centralized feeding system and a feeding method thereof, which is suitable for the centralized feeding of multi-component plastic particles in injection molding equipment. Background technique: At present, the feeding system of plastic particles generally adopts the vortex centrifugal fan conveying method. The fan is noisy and expensive. A single fan only conveys one type of material. Multi-component feeding requires multiple fans to work at the same time. The overall cost is high and noisy. It is too large and has high requirements for materials. When conveying dusty materials or returning materials, the dust removal effect is poor, which seriously pollutes the air environment of the factory. Technical realization elements: The purpose of the present invention is a multi-component centralized feeding system and a feeding method thereof. After the multi-component centralized feeding system is adopted, the noise is low, the cost is low, and the air pollution to the factory is small. A multi-component centralized feeding system and its feeding method are realized by adopting the following technical solutions: A multi-component centralized feeding system includes a vortex fan, a particle filter device, a dust filter device, an air filter device, a suction hopper, a raw material silo, a storage hopper (silo) and a mixing silo. The air inlet of the vortex fan is connected with the particle filter device through an air duct, the particle filter device is connected with the air inlet valve, the main exhaust pipe, and the air inlet pipe of the particle filter device through the pipeline, and the air outlet of the vortex fan is connected with the dust filter device. The particle filter device is equipped with a sponge filter element, and the bottom of the particle filter device is equipped with a collection box, which is used to collect the fine particles filtered by the sponge filter element for recycling and reuse.  The multi-component centralized feeding system is equipped with a backup particle filter device and a backup vortex fan. The backup particle filter device is connected to the backup particle filter device's air inlet valve, main exhaust pipe and induced draft pipe through a pipeline. The backup vortex fan outlet and dust The filter device is connected. The spare particle filter device is equipped with a sponge filter core, and the bottom of the spare particle filter device is equipped with a spare collection box for collecting and recycling the fine particles filtered by the sponge filter core. When the particle filter device needs to be cleaned, close the air inlet valve of the particle filter device and open the air inlet valve of the spare particle filter device. The suction process is the same as the above and continuous. Clean the particle filter device, the suction process is continuous without stopping the machine. The upper part of the suction hopper is equipped with a sub-exhaust pipe. The sub-exhaust pipe is connected to the main exhaust pipe through the sub-exhaust pipe control solenoid valve, and the main exhaust pipe is connected to the air inlet of the particulate filter device through the air inlet valve and pipe of the particulate filter device. , The exhaust port of the particle filter device is connected with the air inlet of the vortex fan through the draft tube. One side of the suction hopper is connected to the raw material silo through a suction pipe. The lower part of the suction hopper is equipped with a discharge valve and is connected to the storage hopper (silo) through a pipeline. The storage hopper (silo) is connected to the mixing silo through a discharge valve and a pipeline. A filter screen is installed in the suction hopper to filter the particulate material. The lower part of the storage hopper (bin) is equipped with an electronic scale. The storage hopper (bin) is weighed by an electronic scale, and the material is quantitatively fed to the mixing hopper of the equipment (twin screw extruder). The upper part of the storage hopper (bin) is equipped with an upper material level gauge to control the upper material level. After the material level is full, the PLC programmable controller controls to close the sub-exhaust pipe control solenoid valve, and the sub-exhaust pipe stops exhausting and stops the suction pipe Suction, the suction hopper stops feeding. The bottom of the storage hopper (bin) is equipped with a lower material level gauge to control the lowest material level. When the particle level reaches the lowest level, the PLC programmable controller opens the sub-exhaust pipe control solenoid valve, and the sub-exhaust pipe exhausts , So that the suction tube sucks the material, and the suction hopper loads the material. The end of the air intake pipe is connected with the air filter device through an air intake valve. The air filter device adopts an air filter and is provided with an air filter element. The air intake valve is controlled by a solenoid valve. The dust filter device is equipped with a dust filter tube, and a dust collection bag is installed at the outlet of the dust filter tube to collect dust. There are at least two vortex fans. At least two said suction hoppers, raw material warehouses and storage hoppers (bins) are respectively provided. A multi-component centralized feeding system is equipped with an electrical control box, equipped with a PLC programmable controller, relay, and electrical control switch. The PLC programmable controller is used to control the vortex fan, the air inlet valve of the particle filter device, and the sub-exhaust pipe Control solenoid valve, solenoid valve, upper material level gauge, lower material level gauge and electronic scale. The vortex fan and the standby vortex fan are commercially available high-pressure vortex fans. The working principle of a multi-component centralized feeding system is the continuous suction of negative pressure vacuum. Under the suction of the vortex fan, the material uses air as the conveying medium, and the multi-component materials enter the suction hopper through the suction pipe from the raw material warehouse. The filter in the suction hopper filters the particulate material and discharges air, dust and fine particles. After the suction hopper is full, the signal prompts that the sub-exhaust pipe control solenoid valve is closed, and the particulate material falls into the storage bin. After the suction hopper is emptied, The sub-exhaust pipe controls the solenoid valve to open, and circulates the previous actions until the storage hopper is full. Multiple sets of suction hoppers can work at the same time. Air, powder, and fine particles are discharged into the atmosphere through the particle filter device and the powder filter device; When all storage bins are full, close all suction hopper valves and open the air filter valve. The vortex fan can work continuously without shutting down; when the particle filter needs to be cleaned, close the air inlet valve of the particle filter and open the backup particle filter device The intake valve, the suction process is the same as above, continuous. Clean the particle filter device, the cleaning is completed, the suction process is continuous, without stopping the machine.

|

Important equipment of central feeding system |

| Dehumidification dryer | gravimetric blender | Plastic weighing mixer |

|

|

|

Central feeding system technology and equipment |

| This is the manufacturer of Cost-saving budget central feeding system flow chart https://global.wto-btb.com Information provided |

| ( https://global.wto-btb.com It is a free service platform for global suppliers) |

| Links: | plastic dryer | Dehumidifying Dryer | gravimetric blender | Central feeding system |

| company name: | Dongguan Machinery Equipment Co., Ltd.(东莞市机械设备有限公司) |

| Phone/WeChat: | +86-13669807274 | Whatapp: | +86-13669807274 | E-mail: | wto-btb@wto-btb.com |

| Address: | 168 Guangming New Street, Dongcheng District, Dongguan City, Guangdong Province, China |

| Website real name: | Central feeding system | copyright: | Central feeding system |

| industry search: | Central feeding system | Central conveying system | ©2007-2029 @ |