| 3 in 1 dehumidifying dryer Details description |

|

| product name:3 in 1 dehumidifying dryer |

| release time:2020-08-12 |

| Numbering:002 |

| Brand:wtobtb |

| Price:¥discuss personally |

| weight :310 |

| unit weight:KG |

manufacturer:WTO-BTB |

| patent:WTO-BTB |

| Producing country:CHINA |

| simple description:This machine has three functions of dehumidification, drying and two-stage feeding, and can choose a one-to-many system, widely used in all kinds of plastic raw materials, especially engineering plastics with strong hygroscopicity, such as PA, PC, PBT, PET, etc |

| Product alias:dehumidifying dryer ,plastic resin dryers,dryer for plastic resin,central drying system |

|

| 3 in 1 dehumidifying dryer Product introduction |

|

3 in 1 dehumidifying dryer parameter

| Model |

HCF-200300 |

| Dryer Hopper |

Capacity (KG) |

300 |

| Heat Protection Material |

Fiberglass+Staninless Steel |

| Dry-Air Dew point |

-35℃ to -45℃ |

| Temperature (℃) |

80-180 |

| Air Flow (m^3/h) |

200 |

| Blower Power (KW) |

2.2 |

| Regeneration Blower (KW) |

0.375 |

| Drying Heater (KW) |

18 |

| Regeneration Heater (KW) |

7.2 |

| Pipe Sizes |

Drying (mn) |

63 |

| Cooling (lnch) |

3/4" |

| Regeneration (mn) |

51 |

| Conveying Blower (KW) |

2 |

| Conveying Distance (m) |

Stage 1 |

6-10 |

| Stage 2 |

6-10 |

| Hose Size (Inch) |

1.5 |

| Sensor Hopper Capacity (L) |

7.5 |

| Vacuum Hopper Capacity (L) |

7.5 |

| Dimension LxWxH (cm) |

123×95×239 |

| Approx.Net Weight (KG) |

420 |

Remark: Compressed air Pressure must more than 0.4MPa,air flow more than 15L/H;

We reserve the right to change spencifications without prior notice.

Product alias:dehumidifying dryer ,plastic resin dryers,dryer for plastic resin,central drying system |

3 in 1 dehumidifying dryer Equipment principle

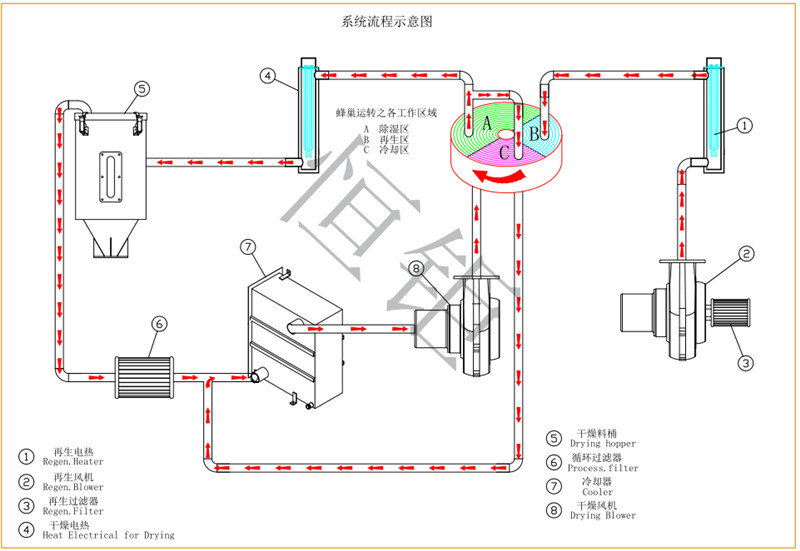

The working principle of the honeycomb wheel type three-machine dehumidification dryer:

1. Dehumidification and drying part: The hot and humid air in the drying drum is cooled and blown into the honeycomb flow channel; the water in the air is absorbed by the wheels, and then absorbed by the regenerated heated air. The two air streams act simultaneously. As the wheels rotate, the water in the air is continuously absorbed and desorbed by the regenerated air and discharged, thereby forming a stable low dew point air. After being heated to the drying temperature of the plastic, it is blown into a drying drum to form a closed loop and dry the raw material.

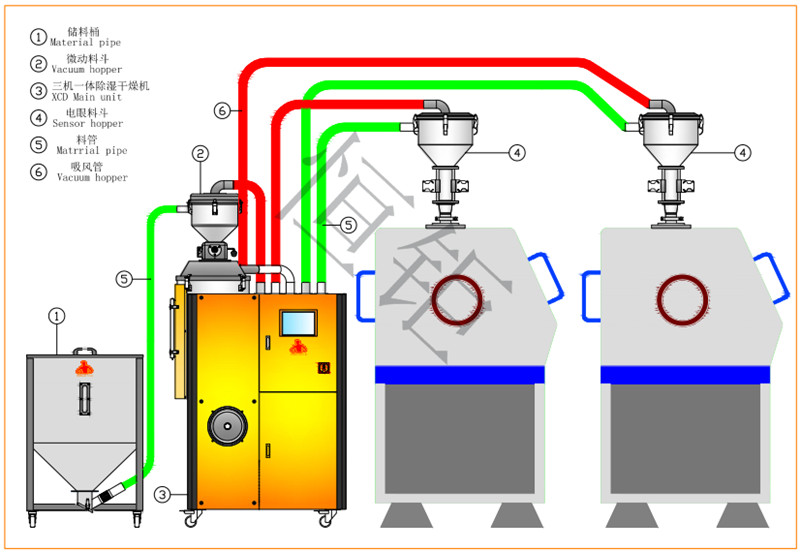

2. Suction part: The suction is sucked into the dry material bucket from the material storage barrel or other storage bin container. When the vacuum hopper's magnetic spring switch detects no material, the suction motor runs to create a vacuum in the vacuum hopper.The raw materials in the storage barrel are sucked into the vacuum hopper due to the difference in air pressure. When the suction time is completed, the suction motor stops running and the raw materials will fall into the dry material barrel due to their own weight.The dried material is pumped from the drying drum into the electric eye hopper installed in the plastic forming machine.

Product alias:dehumidifying dryer ,plastic resin dryers,dryer for plastic resin,central drying system |

3 in 1 dehumidifying dryer application

Features:

1, set dehumidification, drying, two feeding three functions in one, and can choose a one-to-many system.

2. The dehumidifying part is equipped with a wheel device, which can provide low dew point air with good stability, and the dew point can reach below -40℃;

3, stainless steel double-layer heat preservation drying drum adopts downblown air pipe design, make raw materials evenly dry, and effectively prevent heat loss;

4. The feeding system is equipped with cutting valve to ensure that there is no residual raw material in the feeding tube;

5, the loop closed feeding system, can avoid raw materials pollution or moisture return;

6. Adopt high degree of automation, can choose touch control man-machine interface, internal use of programming controller Siemens PLC as the main control;

7. Optional dew point meter, convenient for monitoring dew point at any time;

8, optional suction box and automatic packing machine, easy to transport raw materials

9. When it is changed to conform to the safety loop type of European standard, "CE" shall be added after the type.

Product alias:dehumidifying dryer ,plastic resin dryers,dryer for plastic resin,central drying system |

3 in 1 dehumidifying dryer Precautions

Notes for machine use:

1. Please carry out electrical construction in accordance with the "Electrical Equipment benchmark", "Internal line Provisions" and the provisions of this operation manual.

2. Please do not use the power outside the specified power source.

3. Please complete the specified grounding works.(Yellow power cord)

4. Please tighten the connectors and connecting terminals of the machine body and the electric wires of the meter and meter.

5, please do not break the wire, do not put pressure on the wire, do not put heavy objects on the wire, do not clamp the wire.It could cause an electric shock.

6. Wiring and inspection shall be carried out by professional technicians.

7. When the machine needs to be disassembled due to inspection and cleaning, please cut off the power supply and compressed air source first.

8. Before line detection, the power must be cut off, and the voltage shall be measured with a multimeter 10 minutes later to ensure safety before detection.

9. Do not open the door of the control box during power supply.

10. Wet hands are not allowed to touch the machine body, control department and other accessories.

Product alias:dehumidifying dryer ,plastic resin dryers,dryer for plastic resin,central drying system |

|

|