| Weighing mixing mixer Details description |

|

| product name:Weighing mixing mixer |

| release time:2020-08-13 |

| Numbering:Weighing mixing mixer 001 |

| Brand:wtobtb |

| Price:¥By function |

| weight :By function |

| unit weight:Kg/set |

manufacturer:WTO-BTB |

| patent:WTO-BTB |

| Producing country:CHINA |

simple description:● Adopt high-precision weighing controller to ensure reliable performance and easy maintenance;

Mainly used for: automatic and accurate weighing and mixing of granular materials such as plastic, resin, PE, pet, PPO, PC, TPE, PVC, PLA, TPU, etc.

|

| Product alias:Gravimetric blender、Weighing mixture equipment、Weighing and mixing metering equipment、Gravimetric batch blender |

|

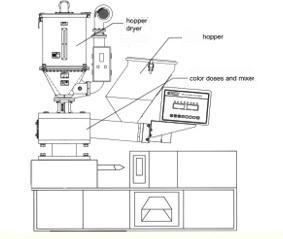

| Weighing mixing mixer Product introduction |

|

Weighing mixing mixer parameter

Product introduction of weighing mixer

The weighing-type mixing mixer is suitable for the occasions where a variety of raw materials need to be accurately mixed according to the weight ratio in the plastic injection, extrusion or hollow molding process. The controller of this series of products adopts the German Siemens PLC control system, and adopts advanced batching algorithm. It can be automatically calibrated every time it is turned on to ensure accurate accuracy and easy to learn and convenient operation. This series of products uses a high-precision weight sensor to control the batch mixing ratio error (depending on the set ratio) within ±0.1%~0.3%. Choose the appropriate model according to the number of types to be processed and the amount per hour. This series of products is divided into twelve models.

| model |

SGB-50 |

SGB-100 |

SGB-200 |

SGB-400 |

SGB-600 |

| H(mm) |

1010 |

1050 |

1225 |

1405 |

1675 |

| W(mm) |

605 |

670 |

815 |

850 |

975 |

| D(mm) |

640 |

700 |

700 |

700 |

960 |

|

Bottom bracket(mm)(HxWxDxBxAxC) |

142x240x240

x150x110x13 |

142x240x240

x150x110x13 |

200x313x323

x180x150x13 |

196x313x323

x180x150x13 |

196x413x423

x220x180x13 |

| Mobile tripod(mm)(H1xH2xWxD) |

700x750

x680x530 |

700x750

x680x530 |

800x850

x780x610 |

800x850

x780x610 |

900x965

x920x725 |

| Net weight (kg) (machine installation type) |

90 |

90 |

130 |

140 |

180 |

| Net weight (kg) (ground installation type) |

110 |

110 |

155 |

165 |

230 |

Product alias:Gravimetric blender、Weighing mixture equipment、Weighing and mixing metering equipment、Gravimetric batch blender |

Weighing mixing mixer Equipment principle

The weighing mixer is used in the injection and extrusion industries where a variety of raw materials need to be accurately mixed in proportion, and the mixing accuracy can reach up to ±0.1%. This series of products all adopt PLC controllers and use advanced batching algorithms to ensure the high quality and comprehensive technical characteristics of this series of products, so that the products have excellent performance, stable operation and safe and reliable operation.

1. Modular and detachable structure design, saving space and convenient cleaning;

2. It can process up to eight kinds of raw materials at the same time; the built-in suction control program can save the cost of suction control;

3. Using PLC controller to ensure stable and reliable performance and easy maintenance;

4. Adopt advanced control algorithm, self-optimization, automatic adjustment compensation and vibration prevention functions to ensure the best batching accuracy;

5. Color graphic display, touch screen operation, online switching in multiple languages;

6. Weighing, volume mixing and metering mode increase the batching capacity; with formula storage function, it can store more than 100 groups of formulas at most;

7. Hierarchical security password control and alarm history record function;

8. The controller is equipped with a standard USB2.0 interface, which can save the mixing ratio data to the U disk, which is convenient for production quality control;

9. With sound and light alarms, it is convenient for the equipment personnel to quickly and accurately reach the faulty machine site.

10 All parts in contact with raw materials are made of stainless steel to prevent raw materials from being contaminated.

11. It can be directly installed on the machine or can be installed next to the machine with optional tripod.

Product alias:Gravimetric blender、Weighing mixture equipment、Weighing and mixing metering equipment、Gravimetric batch blender |

Weighing mixing mixer application

It is mainly used in injection molding workshops or other plastic workshops that require high product quality and uniform coloring. A three-in-one device with automatic weighing, automatic counting and automatic mixing! Accurate measurement can reach a small plastic pellet! Because there is a complex metering system!

Generally applicable to:automatic and accurate weighing and mixing of granular materials such as plastic, resin, PE, pet, PPO, PC, TPE, PVC, PLA, TPU, etc.

For example, if four kinds of materials are to be mixed, and the colors of the four materials are different, it is necessary to accurately weigh and mix the materials! Then use the mixed materials for product production. This equipment can be expanded with 4 colors, 5 colors and other matching machines, which depends on the production needs.

All materials are uniformly mixed after gravity measurement, and the accuracy can be strictly controlled

Advanced batching technology can accurately control and measure the proportion of each processed material

Automatic repeat calibration function, will automatically check the program after each weighing to ensure the best batching accuracy

Up to four raw materials can be processed simultaneously

Removable structure design, easy to clean

With recipe storage function, up to 100 groups of recipes can be stored

The standard equipment is machine installation type (equipped with magnetic base, manual discharge valve), and pneumatic discharge valve is provided as an option

When the machine is used for ground installation, it needs to be equipped with a tripod, pneumatic discharge valve, storage bucket and suction box

With alarm history record function

Optional data storage card to save and record the mixing ratio data to facilitate production quality control

Optional output function of analog signal (0~10V) per hour

Optional batching hopper low level gauge to facilitate early warning when raw materials are lacking

When changing to European safety circuit type, add “CE” after the model

Product alias:Gravimetric blender、Weighing mixture equipment、Weighing and mixing metering equipment、Gravimetric batch blender |

Weighing mixing mixer Precautions

Note: 1) The mixing ratio error refers to the difference between the set percentage of each component ear and the actual percentage;

2) Standard valves are not suitable for powder measurement;

3) The above maximum processing capacity and mixing ratio error data are based on the data obtained by continuous operation of particles with a bulk density of 0.8 and a diameter of 3~4mm.

Product alias:Gravimetric blender、Weighing mixture equipment、Weighing and mixing metering equipment、Gravimetric batch blender |

|

|