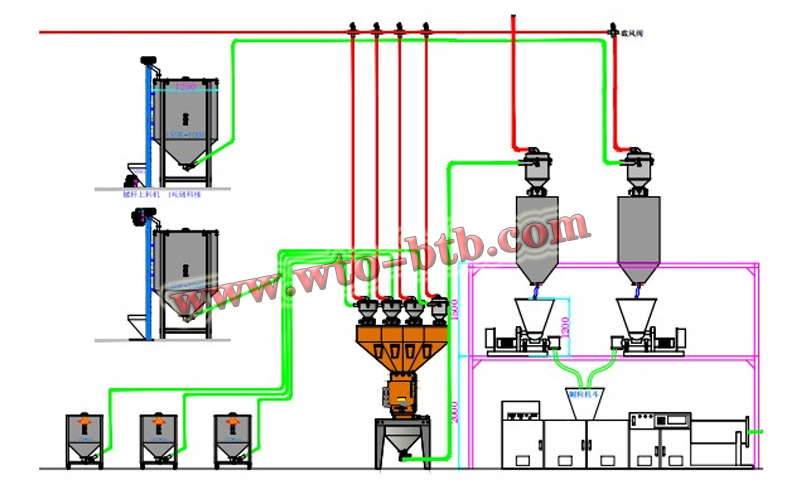

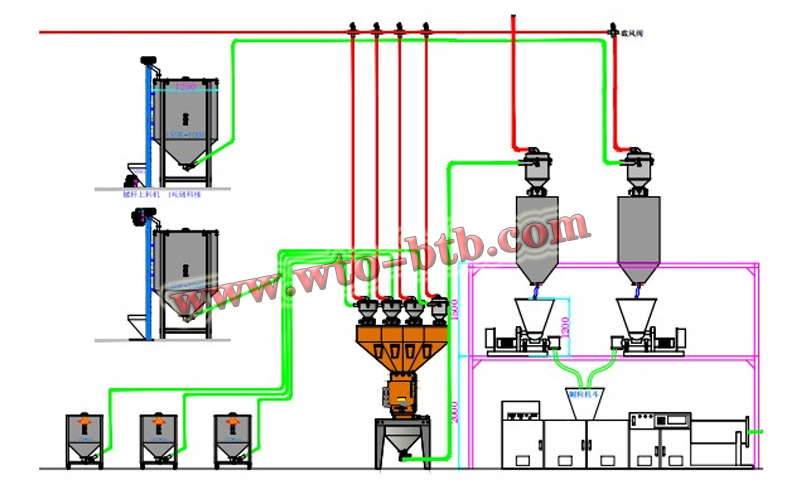

Introduction to the central feeding system of the extruder:

Plastic central feeding system refers to the use of central power source to transport materials to the destination. The plastic central feeding system can use a central vacuum pump to transport materials from a centralized place to various destination machines. The plastic central feeding system can also use a central vacuum pump to transport materials in small bins or bags next to the destination machine. To each destination machine. In addition to the above-mentioned negative pressure conveying method using the vacuum system, the central feeding system of the extruder can also use positive pressure to convey materials from the original packaging to the silo.

Plastic central feeding system. High-efficiency production process. Clean workshop environment. Flexible workshop management. Greatly reduce production costs. Product quality significantly improves the company’s image. The main advantages of the extruder central feeding system are compared with single-machine feeding. Central feeding The main advantages of the system are as follows:

1. The central feeding system of the extruder saves energy. Plastic central feeding system and single feeding equipment

In comparison, the centralized feeding system consumes significantly less energy;

2. The degree of automation of the central feeding system of the extruder is greatly improved;

3. The central feeding system of the extruder has a good and clean production environment. Due to the centralized storage or stacking of raw materials and centralized collection of dust, away from the processing and production site, the working conditions near the host are significantly improved, which greatly reduces dust pollution, thereby improving production efficiency and product quality;

4. Optimized management of the central feeding system of the extruder. The plastic processing system of the whole plant can realize unified operation control, mass conveying, continuous feeding, and stable quality.

5. Avoid human error. Through the number of raw material pipes and the setting of controller components, all possible human errors are eliminated;

6. Security. Due to the use of centralized material supply, the equipment noise on the site is reduced, the operation space is enlarged, and the operator does not need to manually handle, load and unload materials;

7. The workload of daily maintenance is less than that of single machine feeding.

ntroduction of the central conveying system of the extruder

|