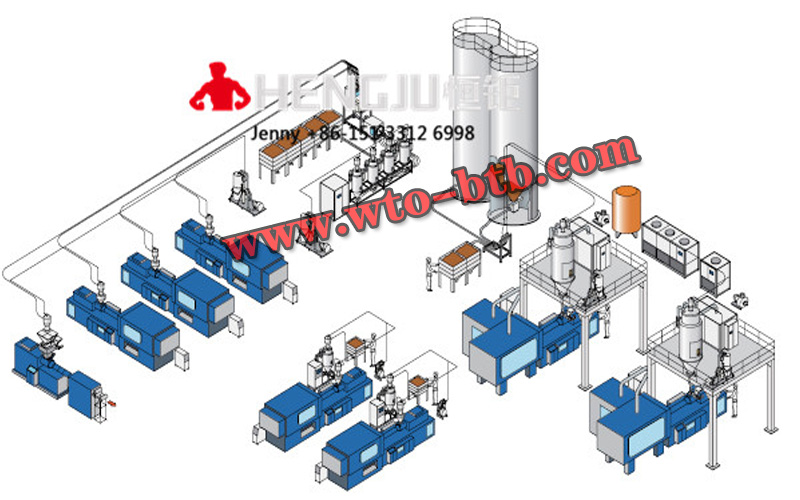

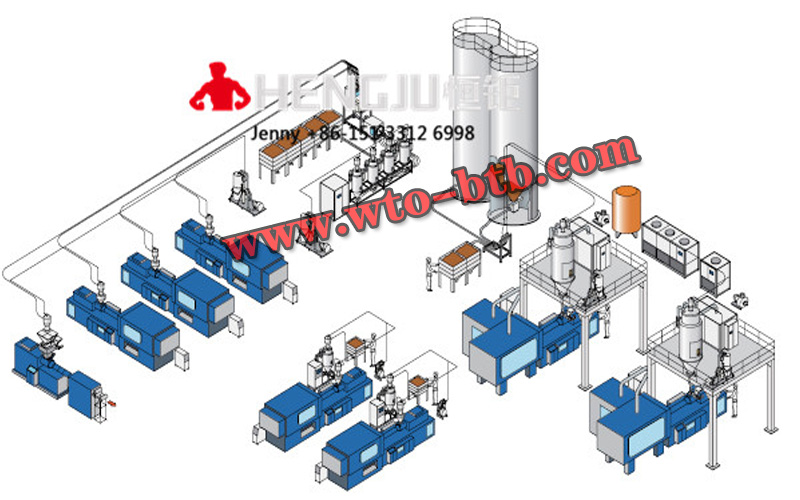

The central feeding adopts the design and construction method of single machine and single pipe to ensure the stable operation of the entire feeding system. The pipeline is in a closed vacuum state during transportation, and there is no material blockage. It is used in conjunction with a central drying system. Dry air can be used to transport the raw materials to prevent drying and cleaning, ensuring that there are no residual pellets in the pipeline. While avoiding the re-moisture of the raw materials, it also ensures that the central feed is added to the injection molding machine. The properties of the raw materials are consistent. Under the action of vacuum negative pressure, the original dust in the raw materials will be filtered out through the dust filter system. We use air filtration after each single suction, install overpressure protection, collect fine dust, and avoid frequent start of the fan It causes loss and is widely used in automobiles, plastic packaging, plastic toys, mobile phone computer digital product shells, food, plastics for daily life, etc.

The following is an introduction to the central feeding equipment system divided into positive pressure conveying and negative pressure conveying.

Positive pressure conveying: refers to the air flow generated by pressurizing the transmitter, and the pressure generated by the air flow pushes the material to form in the pipeline

Vertical or horizontal movement. The material is transported from the transmitter to the receiving bin through the pipeline, while the gas and the material are separated by the filter, the material is left in the bin, and the gas is discharged into the atmosphere through the filter. The controller controls the various parts of the feeder to work in a set sequence. The suitable material forms for positive pressure conveying are: embolic conveying, dense phase conveying and dilute phase conveying.

Negative pressure conveying: The principle is similar to that of positive pressure conveying. The difference is that positive pressure conveying is blowing, and negative pressure conveying is suction.

|