The central feeding system uses technology to process plastics by using conveying technology to physically or chemically process fluids or solid particles, such as drying, leaching, adsorption and ion exchange, particle mixing and other mechanical equipment. The central feeding system is due to It has the advantages of high heat and mass transfer rate, compact structure, convenient dehumidification operation, etc., and is widely used in chemical, food, ceramic, pharmaceutical, medical, electronic and other industries.

The injection molding central feeding system technology originated in 1920. The central feeding system was first used in dehumidification and drying industrial production. During the dehumidification and drying process, the bulk materials were placed on the orifice plate, and the lower part transported gas to make the material particles in a suspended state, like a liquid Like boiling, individual manufacturing companies, design institutes (institutes), universities and colleges have designed and produced part of the central conveying system cylindrical or horizontal multi-chamber fluidized bed, and the injection molding central feed system has begun to contact the plastics industry and industrial industries. .

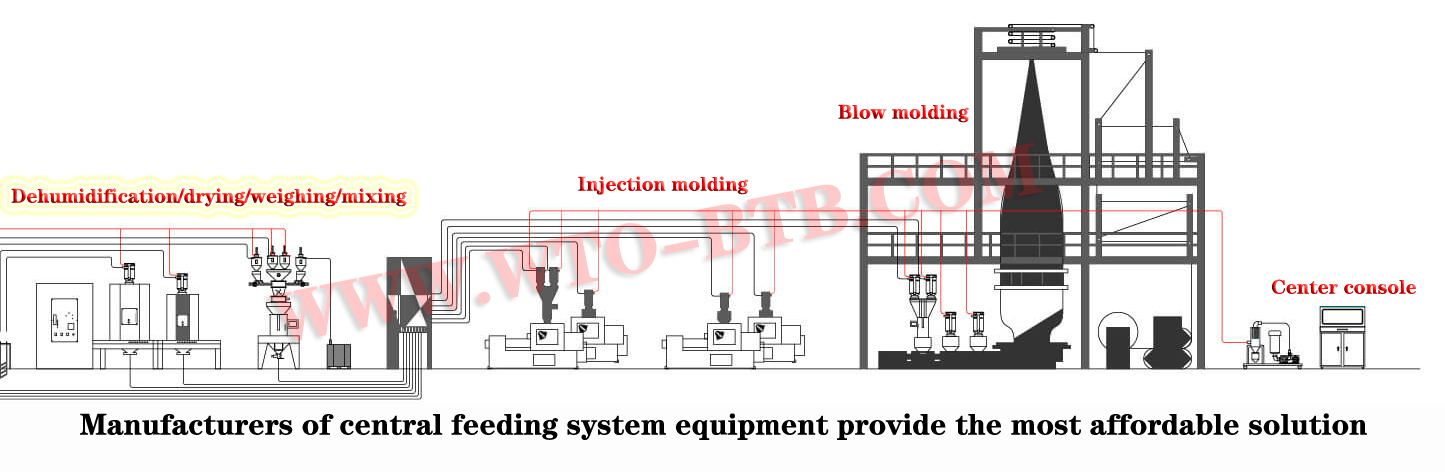

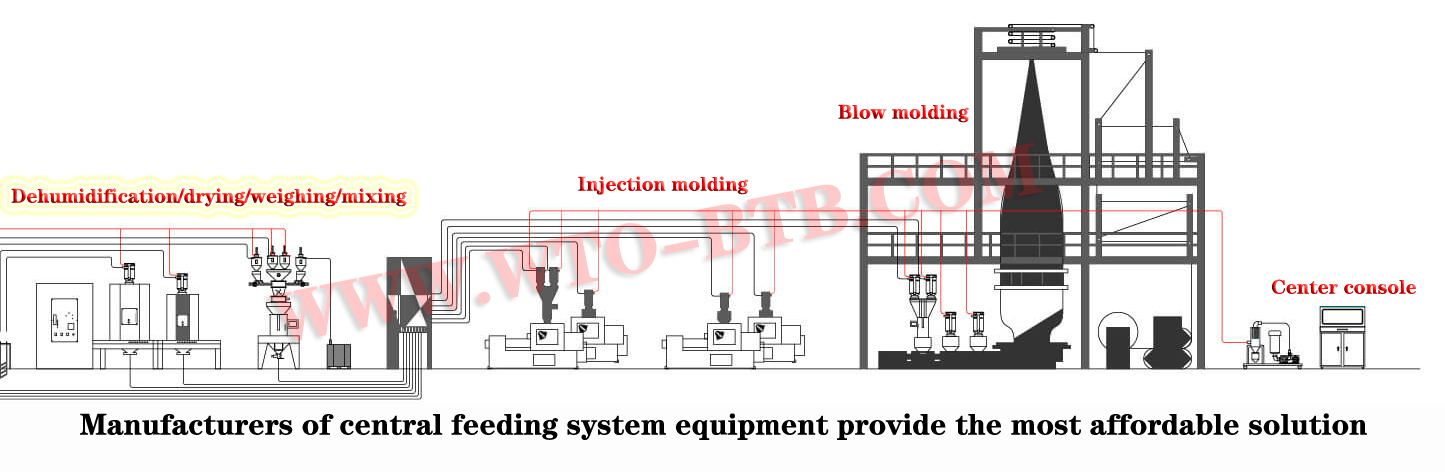

The central feeding system adopts the vacuum conveying method, and the plastic raw materials are transported from the storage tank to the central dehumidifying and drying system through a centralized pipeline system, and then the dried raw materials are transported to each injection molding machine. The central feeding system adopts the design method of "one machine, one pipe" to ensure that the air in the entire system transports the raw materials and prevent the raw materials from regaining moisture after dehumidification and drying. At the same time, each conveying operation is stable, and there is no material blocking phenomenon. It is used in conjunction with the central dehumidification and drying system, which can clean the conveying pipeline after the dehumidification and drying feeding cycle to ensure that there are no residual pellets in the pipeline. While avoiding the regain of the raw materials, it also ensures the performance of the raw materials added to the injection molding machine Consistent.

According to incomplete survey results, the central feeding system is distributed in plastics, plastics, chemical, pharmaceutical and other industries. The materials involved are polytetrafluoroethylene, polyester particles, ammonium chloride, sodium salicylate, anhydrous sodium sulfite, Make the material particles fully contact the gas, and carry out rapid heat transfer and moisture transfer.

|