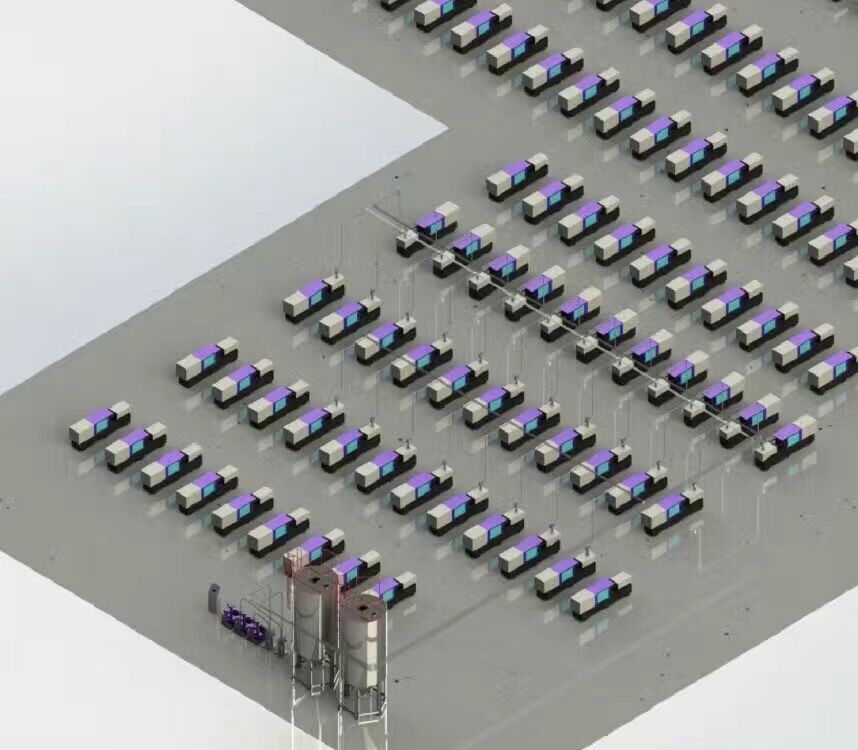

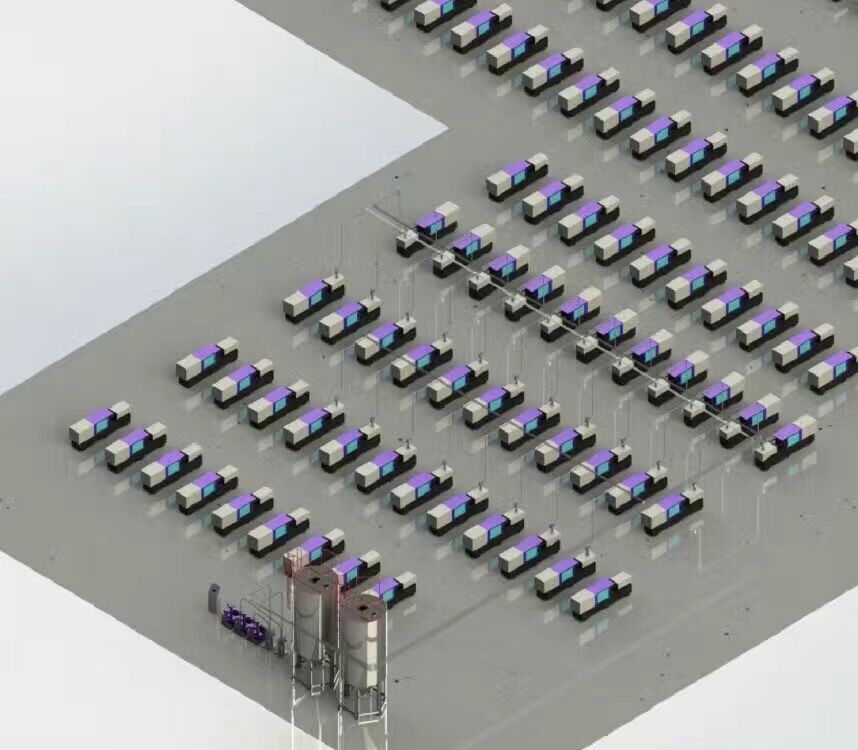

1. The vacuum conveying method is adopted, instead of a centralized pipeline system, the plastic raw materials are quickly transported from the storage tank to the central dehumidification and drying system, and then the dried raw materials are transported to each injection molding machine. Simply put, the central feeding system adopts the design method of "one machine, one pipe" to prevent the re-moisture of the raw materials after dehumidification and drying, and to ensure that the air in the entire system transports the raw materials.

2. The central feeding system is used in conjunction with the central dehumidification and drying system. The conveying pipeline can be cleaned after the dehumidification, drying and conveying cycle to ensure that there are no residual pellets in the pipeline, which can well avoid the phenomenon of raw material resurgence and also ensure The performance of the raw materials added to the injection molding machine is consistent. Under the action of vacuum negative pressure, the original dust in the raw material will be filtered out through the dust filter system, which is of great help to improve the quality of the molded product. In addition, the central feeding system is stable in each conveying and running, and there is no material blocking phenomenon.

|