Several feeding methods of central feeding system

There are several feeding methods in the upper hopper of the central feeding system. Spring feeding system, central feeding system, automatic feeding system, centralized feeding system, automatic feeding system, vacuum feeding and compressed air pipeline transportation can be adopted. Feeding and other methods. It can be roughly divided into the following ways:

1. Central feeding system device: mainly composed of fan, suction pipe, storage bin, suction pipe, filter screen, electric control box and other parts.

When the hopper of the feeding system needs to be loaded, the fan 2 is started, and the negative pressure is formed in the intermediate storage bin through the suction pipe 4 and the filter screen 3; at the same time, the suction connected with the intermediate storage bin and the raw material box The feed pipe 8 sucks the raw materials in the raw material box into the intermediate storage bin. When a certain amount is sucked in, the feeding relay acts, the central system fan stops working, and the suction work stops; at this time, the discharge valve opens, which is the hopper of the extruder. The feed thus goes to the role of the central system.

2. Fully automatic feeding system device:

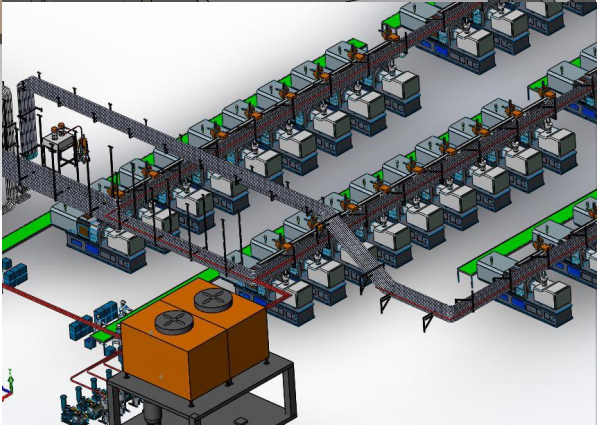

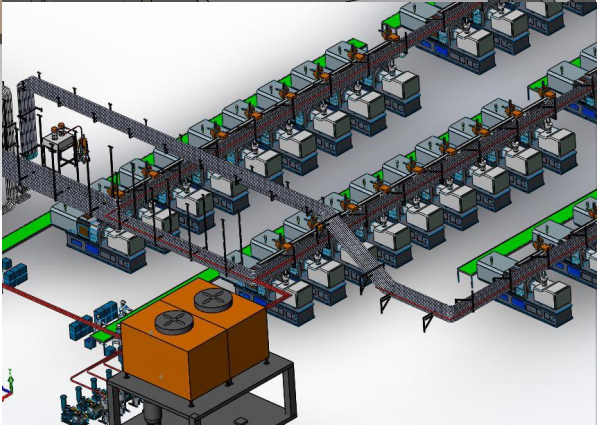

The fully automatic air pipeline conveying and feeding method is mostly used for several extruders in parallel with colleagues to produce and feed. In such a relatively large-scale production extruded product workshop, the conveying system consists of a general feeding pipe and subdivided Several branch pipes are sent out to feed each extruder hopper. This method of relying on compressed air and adopting air pipes to transport materials has a small area, fewer people, and a relatively clean environment. It can be used to transport pellets and powders.

3. Spring feeding system device: It is to install a coil spring in the rubber tube. The spring is directly driven by the motor and rotates at high speed in the rubber tube. When the hopper needs to be loaded, the motor is started to drive the spring to rotate, and the raw material is driven by the spring spiral to rise. The upper end of the rubber tube is aligned with the hopper and there is a discharge opening. The raw material rising to the discharge opening is thrown out by the centrifugal force of the spring rotation.口,Enter the hopper. This kind of feeding device has simple structure, convenient operation and maintenance, and is suitable for conveying pellets and powders.

|