How to choose a cost-effective central feeding system

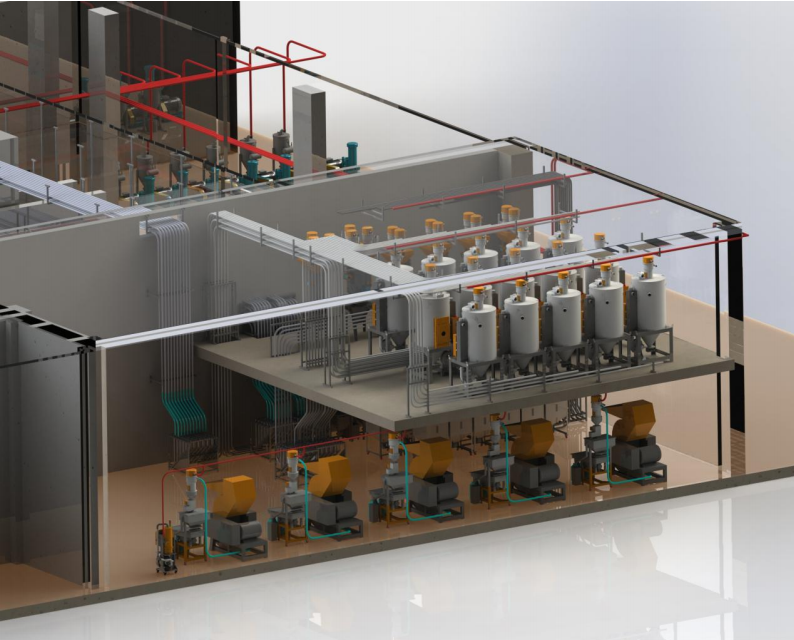

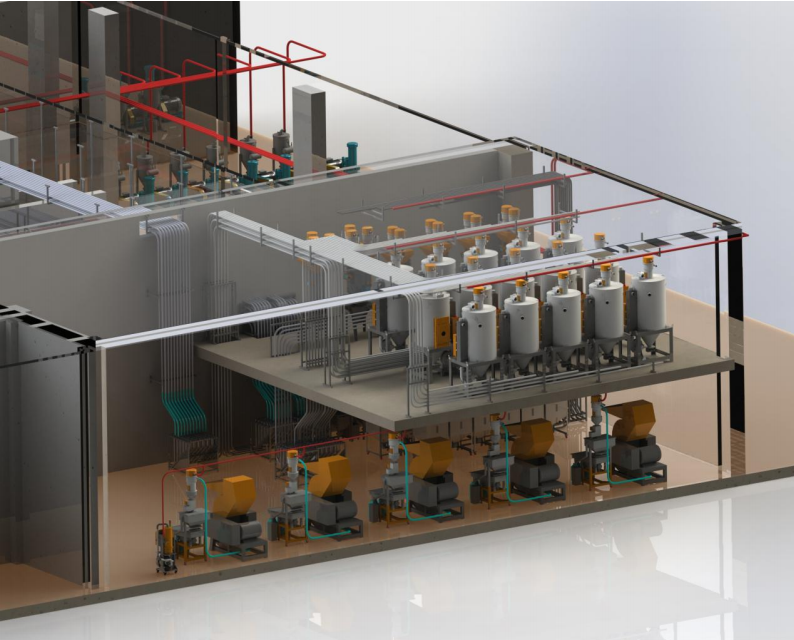

In this ever-changing and fiercely competitive market, automated production can reduce labor and improve product qualification rate, save energy and reduce production costs. The central feeding system is an important equipment in the plastics industry. The central feeding system can flexibly change the feeding volume according to the production volume of different molding machines. The design of multiple supply pipelines ensures the diversified requirements for main materials.

High-quality equipment is improving work efficiency, so how should I choose this type of equipment? Next, I will briefly introduce a few elements of the purchase:

1. Whether the equipment meets your raw materials, most of the domestic granular material conveying equipment.

2. When purchasing related equipment, consider the use of auxiliary equipment such as raw material mixing, color masterbatch addition, and raw material drying.

3. Whether the purchased equipment meets the development planning and production requirements in recent years. If you choose the suction machine to replace the centralized feeding in the future, you only need to replace the head and add a pump set and other devices.

4. The type, amount and conveying distance of raw materials used. The variety of raw materials used, the large amount of materials used, and the long conveying distance will lead to the selection of a centralized feeding system.

|