|

Central feeding system| RSS

|

|

central feeding system |

|

central feeding system |

Instructions for use of central feeding system |

source:Central feeding system Author:Central feeding system time:2020-08-27 10:49:45 |

|||

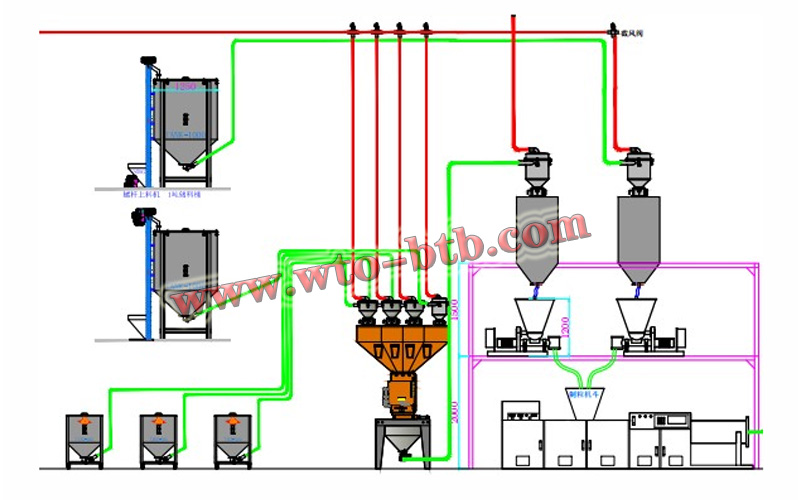

| Instructions for use of central feeding system Manual screen Central feeding system manual alarm screen, Central feeding system manual electrical wiring drawing description A detailed introduction to the manual of the central feeding system Central feeding system instructions for electrical wiring drawing instructions (1) The controller is SIEMENS S7-200, and its output type is relay type, which can directly drive the load. The input type is 24VDC input. It is forbidden to directly introduce 220V into the input side through a switch or sensor! (2) The input power of the touch screen computer display is 24VDC. Please pay attention to waterproof, anti-corrosion, and shockproof when using it. It can be easily operated by touching the corresponding button on the screen. It is forbidden to use metal objects to click on the screen to avoid damage to the touch device! (3) Both the controller and the touch screen need to be well grounded, please ground them strictly according to the drawings! (4) There is 24VDC output on the right side of the controller CPU input terminal, which supplies power to the sensor. The power is very small. It is recommended that customers do not use it to avoid abnormal CPU response. It is forbidden to introduce external switching power supply (or 24VDC power supply) into the output power supply of the CPU sensor, so as not to cause the CPU to malfunction or even damage it! Instructions for the use of the central feeding system  "Machine" refers to the number of the stainless steel hopper on the injection molding machine. "Raw material" refers to the corresponding shutoff valve number under the dryer "Pumping time" sets the working time of supplying materials to the corresponding hopper. The pumping time is the time for pumping materials from the storage barrel to the hopper. If the material is supplied normally, each supply barrel can be used within the set time Full of material. The setting range is 0-999 seconds. Note: All draw time cannot be 0! "Pumping time" sets the pigging time, that is, the shut-off valve is closed, the shut-off valve continues to open, and the remaining material in the pipe is emptied. "Alarm delay ____ times" sets the number of alarm delay output times. We call the machine complete a pumping and emptying action as an action cycle. The number of alarms is set if the machine has completed several action cycles. An alarm will be output when the material is full. The alarm information can appear in the lower left corner of the screen. After setting, touch "Down" to enter "Setting Screen 2" and then set. There are 3 setting screens in total. Touch the button "Start" under "ON/OFF" to turn on the corresponding machine. After selecting the machine that needs to be supplied, touch the button "start" and the system will start to run automatically. To shut down, click the button "Stop" to shut down. After all the materials are full, the fan will automatically delay shutdown according to the delay time setting, and the setting of "0" means no shutdown. Central feeding system instructions for use monitoring screen Touch the "monitoring" screen to switch, monitor the screen This screen displays the working status of the system in physical form. The working status of the cylinder is indicated by the dynamic valve. The green flashing indicates that it is working. To Compare with the site map, please compare the number with the actual site. , The current working conditions and working status of various parts of the feeding system appear in text form. They are "stop, full material, lack of material, pumping, pumping out, abnormal". Shut down, the machine is not turned on; lack of material, the machine is out of material in the hopper; pumping, the machine is pumping; full, the machine hopper is full; abnormal, the machine completes the action cycle times and reaches the set alarm number If the material is not full, an alarm will be output. "Material level" indicates the on-off state, flashing red indicates material shortage, and green indicates full material. To Manual screen for instructions for use of central feeding system In Figure 1, touch the button "Manual", the screen will pop up a password box, enter the password and press "Confirm", the screen enters Figure 5, manual operation can be performed in the manual screen. To Central feeding system instructions and alarm screen Touch the "Alarm" button on the screen to switch the screen* Figure 6: This screen allows you to view the time and location of the abnormality of the supply tank. All alarms can be reset by touching the button "Reset", and the alarm will be eliminated after resetting. When an alarm occurs, the corresponding position siren will be driven. Please check the alarm information and troubleshoot in time! Instructions for use of the central feeding system Clock setting When you need to calibrate the clock, please touch the time display area in the lower right corner of the screen to switch the screen* Please enter the current year, month, day, hour, minute, and second in the "System Clock Settings", and then click the "OK" button. At this time, the system clock will start running from this moment.

|

Central feeding system technology and maintenance |

| Dehumidification dryer | gravimetric blender | plastic granules mixing machine |

|

|

|

| Links: | plastic dryer | Dehumidifying Dryer | gravimetric blender | Central feeding system |

| company name: | Dongguan Machinery Equipment Co., Ltd. |

| Phone/WeChat: | +86-13669807274 | Whatapp: | +86-13669807274 | E-mail: | wto-btb@wto-btb.com |

| Address: | 168 Guangming New Street, Dongcheng District, Dongguan City, Guangdong Province, China |

| Website real name: | Central feeding system | copyright: | Central feeding system |

| industry search: | Central feeding system | Central conveying system | ©2007-2029 @ |