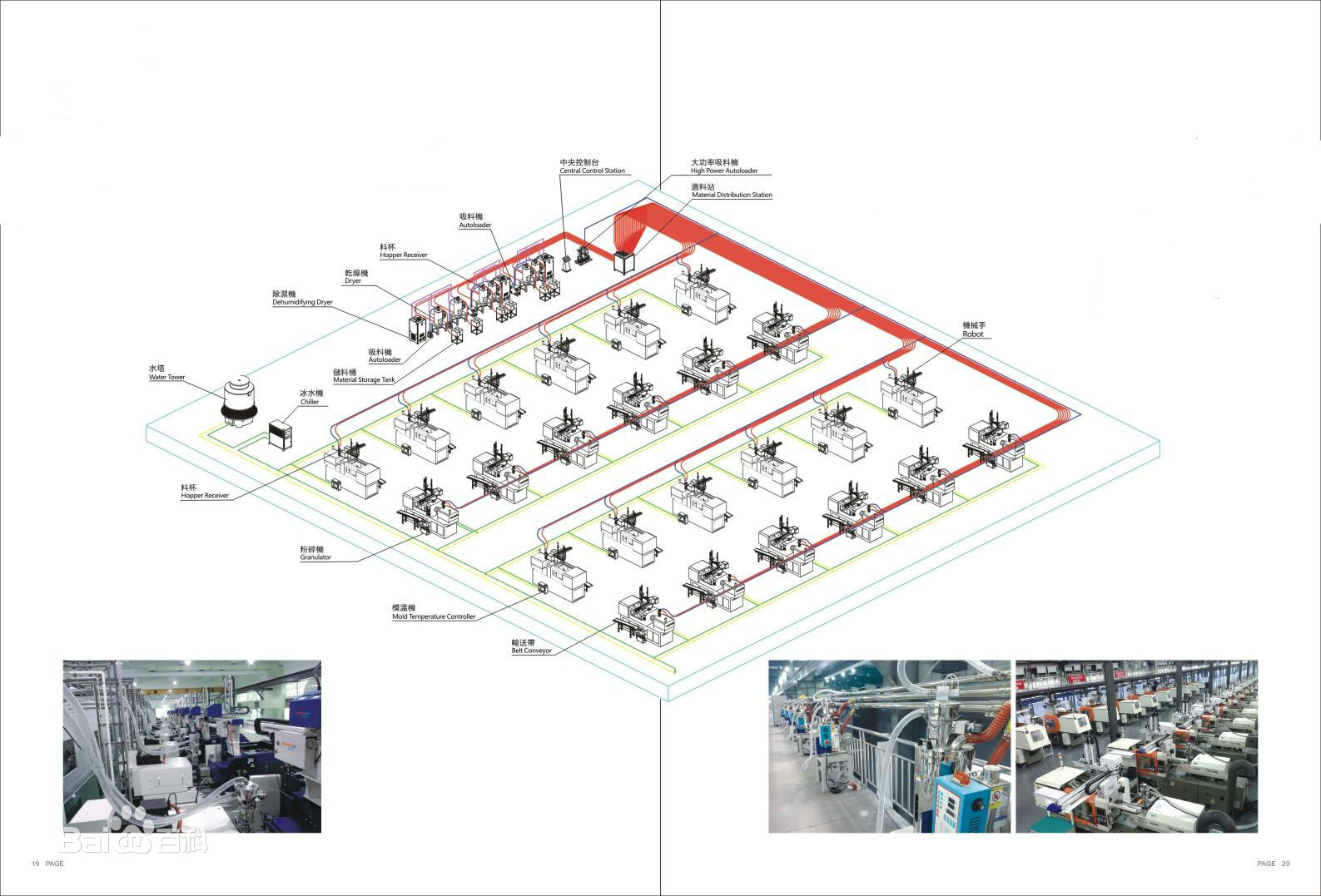

What is a central material feeding system?

The central material feeding system is designed for the production of plastic products in the injection molding workshop, and realizes uninterrupted unmanned continuous molding operations. The variety of raw materials and the combined use of multi-color materials can be changed as needed to realize the automation of the coloring process. The system can regenerate and use the nozzle cold material in a fully automatic way, can control all the feeding equipment, and prevent the occurrence of blockage in the storage bin, and realize full automation by setting up a central monitoring station.

The central material feeding system adopts the microcomputer centralized automatic control, which realizes the continuous feeding operation of pellets for 24 hours. Multiple small microcomputers respectively control the coloring process of each molding machine, the measurement is accurate, the mixing is uniform, and the color can be flexibly changed to meet the requirements of multiple colors and varieties of products. According to the production capacity of different molding machines, the feeding amount can be flexibly changed. The design of multiple feed pipes can ensure the diversified requirements of the main materials. The system has a variety of monitoring and protection functions, and the work is safe and reliable. The aliases of the central feeding system are: centralized feeding system, automatic feeding system, etc.

The working principle of the central material feeding system:

The central material feeding system adopts a vacuum conveying method, and conveys the plastic raw materials from the storage tank to the central dehumidification and drying system through a centralized pipeline system, and then conveys the dried raw materials to each injection molding machine. The central feeding system adopts the design method of "one machine, one pipe" to ensure that the air in the entire system transports the raw materials and prevent the raw materials from regaining moisture after dehumidification and drying. At the same time, each conveying operation is stable, and there is no material blocking phenomenon. It is used in conjunction with the central dehumidification and drying system. The conveying pipeline can be cleaned after the dehumidification and drying cycle to ensure that there are no residual pellets in the pipeline. While avoiding the regain of the raw materials, it also ensures the performance of the raw materials added to the injection molding machine. Consistent. Under the action of vacuum negative pressure, the original dust in the raw material will be filtered out through the dust filter system, which helps to improve the quality of the molded product.

|