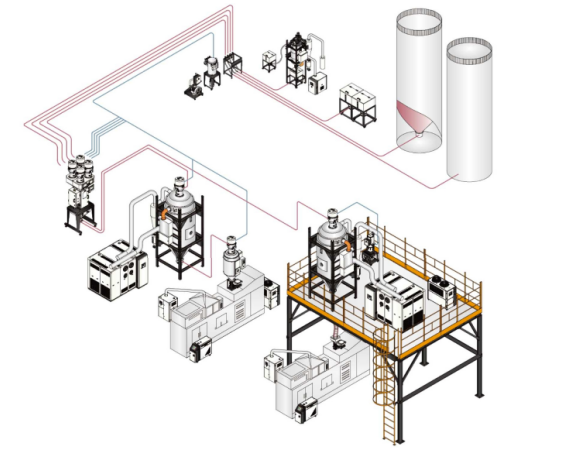

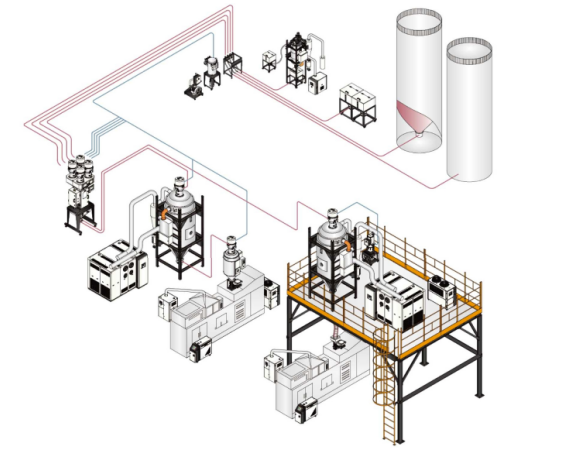

PET preform molding production flow

Relying on its technical strength in the field of plastic auxiliary equipment, we can meet all requirements from plastic transportation, dehumidification and drying, mold temperature and cooling, recycled material utilization, and color management. It adopts smart energy-saving control technology, strictly monitors the raw material processing process, and realizes different systematic solutions tailored to customers.

Automatic conveying system

The parts in contact with the raw materials are made of stainless steel and the filter device of the conveying system, which effectively ensures that the PET raw materials are not polluted during the conveying process. The flexible conveying air supply adjustment system, by adjusting the conveying speed, effectively avoids the situation of drawing or dusting of PET raw materials due to different conveying conditions.

For the conveying system of PET high-temperature raw materials, we has specially designed a solution with water cooling function, which reduces the risk of conveying high-temperature raw materials from the suction machine.

The closed-loop secondary conveying system, the process of conveying the hot material and the heat preservation hopper that needs to be sent to the molding machine after drying, can greatly reduce the heat loss during the conveying process and the moisture absorption of the dried material again. risk.

Drying system

In the process of PET preform system, drying becomes a particularly critical stage. It is necessary to ensure that the moisture in the raw materials is removed and the drying temperature is reasonable. Shini’s desiccant dryers can provide dry air with a dew point of -40°C or lower, and can monitor various parameters in time and ensure a constant dew point.

Dew point setting and smart regeneration function, the dew point temperature of traditional dehumidifiers cannot be set, and the dehumidifiers are working at maximum load. However, when processing PET raw materials requires high humidity, the dew point must be set and controlled. The dew point temperature can be set related to the control of regenerative energy, which reduces energy consumption compared with traditional dehumidifiers.

|