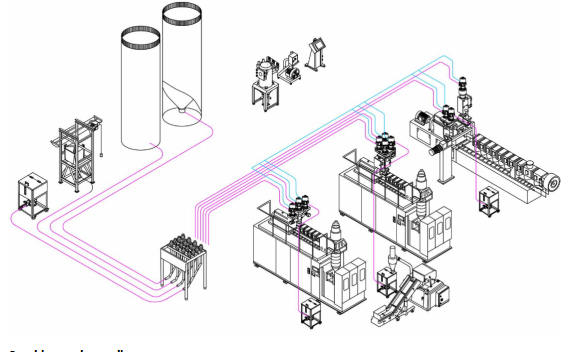

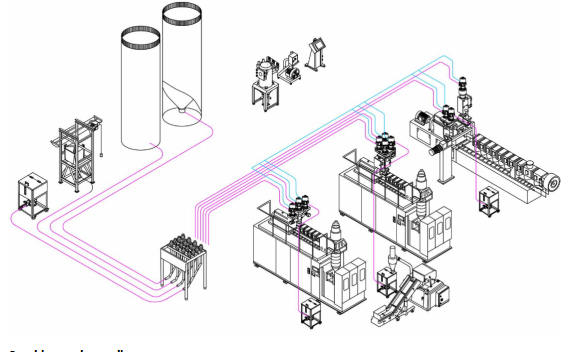

Extrusion blow molding system

The process of blow molding includes two main blow molding methods: extrusion blow molding and injection blow molding. The tubular plastic parison obtained by extrusion or injection molding of thermoplastic resin is placed in a split mold while it is hot (or heated to a softened state), and compressed air is injected into the parison immediately after the mold is closed to inflate the plastic parison It clings to the inner wall of the mold and releases it after cooling to obtain various hollow products. Blow molding is a molding process used to produce hollow thin-walled parts with thermoplastic plastic materials. Its typical products are large-volume final consumer products, such as bottles and containers. At present, the most used plastics in production are PE, PP, and PVC.

Crushing and recycling

For the treatment of defective products, the Xiecheng crusher is suitable for crushing and recycling various plastic products, such as preforms and PET bottles.

The centralized control design is convenient for manipulation; the close to open cutting room design is convenient for cleaning the interior; it is equipped with multiple safety protection devices to reduce damage to people and machines.

Materials dosing and mixing

Volumetric masterbatch mixer

The volumetric masterbatch machine SCM can be used for the measurement of granular masterbatch raw materials, and the production range is 0.2~32kg/hr. If customers have higher requirements for the addition ratio and accuracy of color masterbatches, we recommend the use of a weightless masterbatch machine SGD, which adopts a weightless measurement method, and the production range is 0.04~32kg/hr.

Weighing Mixer

In the extrusion blowing process, the main raw materials, color masterbatch and recycled materials are added in proportion through the SGB weighing mixer. The output range of the weighing type mixing mixer SGB is 40~3000kg/hr, and the metering components range from 2 to 8 components. Equipped with an Ethernet interface, the software is used to upload the produced mixture ratio data through this port, which is convenient for production quality control; at the same time, it can realize centralized monitoring with the machine through this port (based on MODBUS-TCP/IP protocol).

|