|

Central feeding system| RSS

|

|

central feeding system |

|

central feeding system |

How Central Conveying System Work? |

source:Central feeding system Author:Central feeding system time:2020-08-13 14:46:14 |

|||

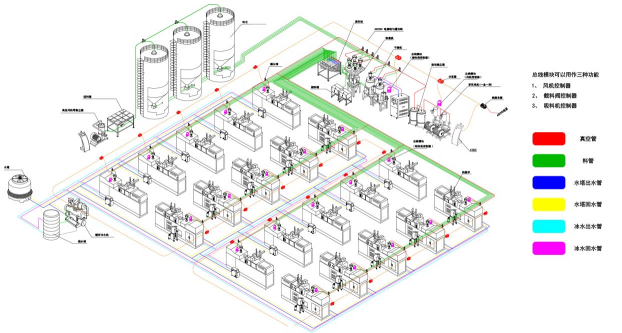

| How Central Conveying System Work? The central conveying system is designed according to the customer's on-site machine placement and the use of on-site raw materials, combined with special auxiliary equipment, which can realize centralized feeding and centralized control, so as to realize the uninterrupted unmanned operation of the whole plant A holistic solution for forming operations. The central feeding system uses industrial computers to automatically centrally control all machines, realizing 24-hour continuous feeding operations for all feeding units. With the special functions of each machine in the system, special requirements such as dehumidification, drying, transportation, metering and mixing of raw materials can be perfectly realized. The central feeding system has a variety of monitoring and protection functions, and its work is safe and reliable. It is the core prerequisite for enterprises to realize unmanned chemical factories.  Storage and Conveying Whether it is a small storage barrel or a large outdoor storage silo, we can provide you with the most suitable storage solution to save space, protect raw materials, and reduce transportation costs. The parts in contact with the raw materials are made of stainless steel and the filter device of the conveying system, which effectively ensures that the raw materials are not polluted during the conveying process. The flexible conveying air supply adjustment system, by adjusting the conveying speed, effectively avoids the situation of drawing or dusting of the raw materials due to different conveying conditions. For the delivery system of high-temperature raw materials, a solution with water cooling function is specially designed to reduce the risk of high-temperature raw material transportation by the vacuum pump. The closed loop secondary conveying system, for the conveying process of the hot material and the heat preservation hopper on the forming machine after drying, It can greatly reduce the risk of heat loss during transportation and the risk of re-absorption of moisture by the dried raw materials. Raw material distribution The standard manual material distribution station uses quick connectors, allowing you to choose the best batching pipeline. The central distributor and its matching connectors can improve the efficiency of the system. The automatic material distribution station is controlled by a central console and can be used for large-scale conveying systems. Extrusion control Cooling air ring and film thickness gauge For plastic film blowing machinery, the air ring is an important component of bubble forming and cooling. The air ring has a great influence on film thickness uniformity and film output. Recycling For the processing of leftovers, the crusher is suitable for various plastic products Crushing and recycling, such as preforms, PET bottles, etc. Centralized control design, easy to control; Close to open cutting room design, easy to clean the inside; Equipped with multiple safety protection devices to reduce damage to people and machines. Industrial refrigeration The screw compressor is relatively more stable, has a longer service life, and has a better cooling effect. BITZER is the best brand of screw compressors in the world (Taiwan Hanbell is also available); With high efficiency shell and tube evaporator, high efficiency shell and tube condenser The heat dissipation efficiency is higher and the cooling effect is better. Mold temperature control Using P.I.D temperature control, the temperature error is ±0.1 degrees, the constant temperature time is long, the efficiency is high, and energy saving The oil return type can easily and quickly realize the recovery of heat transfer oil Six protection functions: automatic exhaust at startup, automatic cooling at shutdown, alarm for thermocouple breakage, Power supply phase loss, out-of-phase protection, water pump protection, overheat protection, oil shortage, etc. Material drying Prevent the dried raw materials from getting damp again due to contact with outside air, and improve the drying effect Evenly disperse hot air, stable temperature, and effectively keep the plastic dry; With overheating protection device to reduce accidents caused by man-made or mechanical failures, It can also be set to automatically switch on and off for a week, saving energy and electricity; Automatic conveying The parts in contact with the raw materials are made of stainless steel and the filter device of the conveying system, It effectively ensures that the raw materials are not polluted during the transportation process. Flexible conveying air supply adjustment system, by adjusting the conveying speed, Effectively avoid the situation of wire drawing or dust caused by different conveying conditions. Dosing and mixing The blender controller of the weighing mixer is equipped with an Ethernet interface. With the corresponding software, the raw material ratio data can be read through this communication interface (Such as maximum output, actual output, ratio accuracy) to facilitate product quality control. Automatic repeat calibration function, The program will be automatically checked after each load bearing to ensure the best matching accuracy. It has the function of automatic compensation for recycled materials, which can automatically calculate color difference compensation according to the amount of recycled materials.

|

Central feeding system technology and maintenance |

| Dehumidification dryer | gravimetric blender | plastic granules mixing machine |

|

|

|

| Links: | plastic dryer | Dehumidifying Dryer | gravimetric blender | Central feeding system |

| company name: | Dongguan Machinery Equipment Co., Ltd. |

| Phone/WeChat: | +86-13669807274 | Whatapp: | +86-13669807274 | E-mail: | wto-btb@wto-btb.com |

| Address: | 168 Guangming New Street, Dongcheng District, Dongguan City, Guangdong Province, China |

| Website real name: | Central feeding system | copyright: | Central feeding system |

| industry search: | Central feeding system | Central conveying system | ©2007-2029 @ |