|

Central feeding system| RSS

|

|

central feeding system |

|

central feeding system |

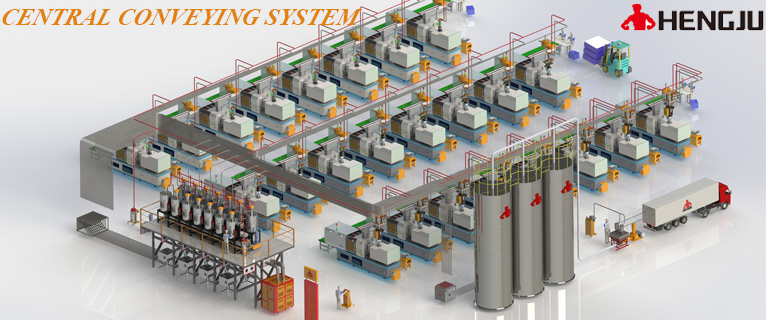

Analysis of injection molding of centralized conveying system |

source:Central feeding system Author:Central feeding system time:2020-09-02 14:48:54 |

|||

| Analysis of injection molding of centralized conveying system There are many types of plastic molding methods in the central conveying system, and each method has its own different characteristics! There are mainly the following methods for plastic molding in the centralized conveying and feeding system: 1. Injection molding: Plastics are first heated and melted in the heating barrel of the injection molding machine, and then the reciprocating screw pushes the melt into the cavity of the closed mold for molding. 2. Extrusion molding: a method in which the plastic is continuously passed through the die in a flowing state by heating and pressing in an extruder. 3. Foam molding: refers to the processing method of adding proper foaming agent to foam material to produce porous or foamed products. 4. Blow molding: refers to a molding method in which the hot thermoplastic parison or sheet in a closed mold is blown into a hollow product by means of fluid pressure. Pay attention to the following points when using the central feeding system: 1. Before starting, the driving wheel should be moved one or two laps by manpower. After confirming that the movement is flexible, the central feeding system should be opened for operation, and the feeding should be performed after the central feeding system is operating normally.  2. Pay attention to the temperature of the bearing during operation, keep the bearing in a good lubrication state, and pay attention to the sound and Whether the vibration is abnormal. When an abnormal situation is found, the first step should be to stop the machine and check whether it is stuck by something that is not easily broken, or The central feeding system is damaged. 3. Check whether the particle size of the crushed product meets the requirements. If there are too many particles exceeding the specified size, the reason should be found (such as The screen bar gap is too large, the discharge port is too wide, the hammer is worn out, etc.), and appropriate measures should be taken to deal with the problem. 4. It is necessary to maintain uniform feeding of plastic central feeding system products to prevent overload. Strictly prevent metal and wood from breaking The object falls into the machine. When it cannot be crushed, the feed water content cannot be too high; when wet crushing, proper water is needed to prevent Clogging due to insufficient flushing water reduces production capacity. 5. Worn out parts should be replaced or repaired in time. 6. The safety device of the central feeding system must be kept in good condition. It must not be an effort to make the safety device invalid. 7. When the central feeding system is shut down, check whether the fastening bolts are firm and the degree of wear of the easily worn parts . Such as If you pay more attention to it in daily use, you can make the central feeding system more durable and more profitable for the enterprise. 8. Before stopping the operation of the central centralized feeding system, you should stop feeding and drain the materials in the machine first, and then cut off the power of the motor! Advanced design concept. Dedicated to: 1. Large-scale plastic powder and granular raw material unloading, storage, transportation, raw material ratio system turnkey engineering and professional transportation engineering valve manufacturing. 2. Design and construction turnkey project and centralized supply of raw materials for plastic unmanned workshop. 3. Automatic auxiliary equipment: automatic non-standard equipment such as dehumidification dryer, chiller, mold temperature machine, grinder, mixer, automatic proportioning mixer and so on.

|

Important equipment of central feeding system |

| Dehumidification dryer | gravimetric blender | Plastic weighing mixer |

|

|

|

Central feeding system technology and equipment |

| This is the manufacturer of Analysis of injection molding of centralized conveying system http://global.wto-btb.com Information provided |

| ( http://global.wto-btb.com It is a free service platform for global suppliers) |

| Links: | plastic dryer | Dehumidifying Dryer | gravimetric blender | Central feeding system |

| company name: | Dongguan Machinery Equipment Co., Ltd.(东莞市机械设备有限公司) |

| Phone/WeChat: | +86-13669807274 | Whatapp: | +86-13669807274 | E-mail: | wto-btb@wto-btb.com |

| Address: | 168 Guangming New Street, Dongcheng District, Dongguan City, Guangdong Province, China |

| Website real name: | Central feeding system | copyright: | Central feeding system |

| industry search: | Central feeding system | Central conveying system | ©2007-2029 @ |