With the application of scientific and technological progress in production, the production industry has gradually shifted from traditional manual labor to automation, and intelligence has also developed to a certain extent. The application range of automatic batching systems is very wide, including chemical batching, grain weighing, concrete mixing, and glass batching , Coal blending control, pharmaceutical factory batching control, ceramic batching, etc. However, some enterprises still use traditional methods for production due to many factors, and rely on manual labor in the batching process. Because manual operation has greater subjectivity and randomness As a result, it is difficult to guarantee accuracy in terms of accuracy, and it is easy to cause economic losses for the enterprise in the case of large-scale production. From the perspective of cost control and profit, it is necessary to improve production efficiency to ensure quality, and the application of automation technology can effectively solve this One problem is to reduce labor costs and standardize and unify work results.

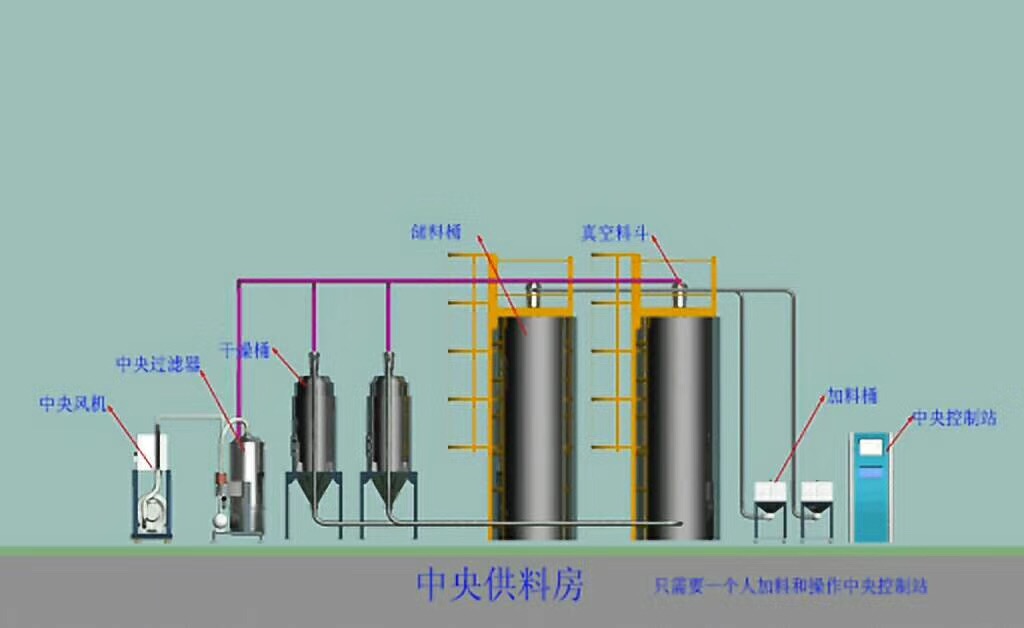

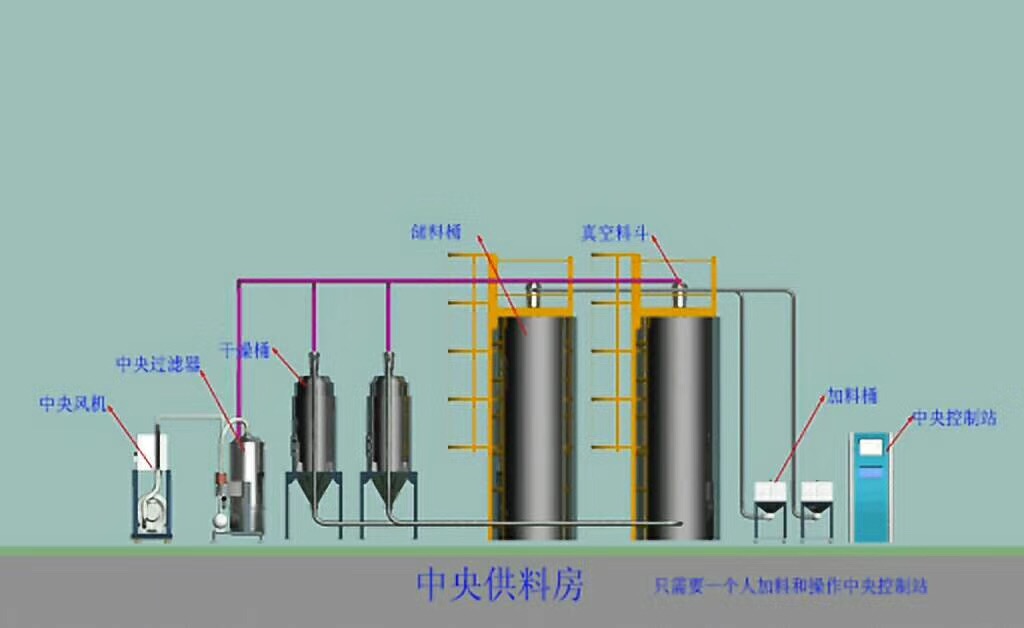

The central feeding system is closed in the chemical application process. In the display screen of the console, you will understand the whole production process, the amount of materials, automatic color matching of materials, automatic weighing of materials, automatic distribution of materials, automatic dehumidification and drying of materials, and automatic feeding of materials , Automatic alarm and other automation systems! And can reduce personnel safety risks, air pollution and other benefits!

|