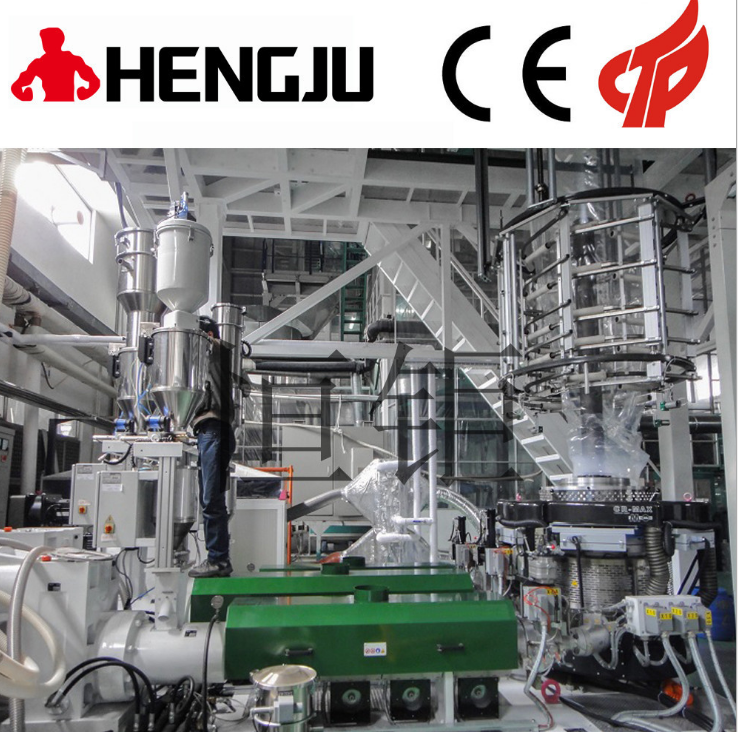

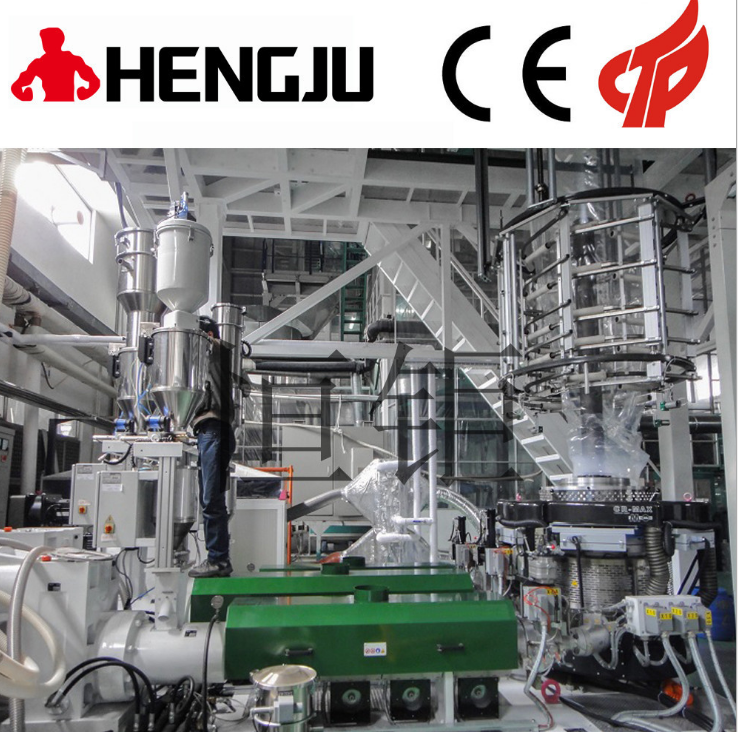

With the continuous development of the plastic production industry, it needs to be applied to the feeding equipment that meets its production requirements. The centralized feeding system of the injection molding machine was born. For the production site, the centralized feeding system of the injection molding machine combines the raw materials and the drying barrel It is completely separated from the site and the feeding system. Do you know what are the advantages and disadvantages of the centralized feeding system for injection molding machines? save space. Now many manufacturers have applied the centralized feeding system for injection molding machines!

Advantages of centralized feeding system for injection molding machine:

1. The centralized feeding system of the injection molding machine adopts a single-machine and single-pipe design and construction method to ensure the stable operation of the entire centralized feeding system of the injection molding machine. The pipeline is in a closed vacuum state during transportation, and there is no blockage.

2. The central feeding system of the injection molding machine is used in conjunction with the central drying system. Dry air can be used to transport the raw materials to prevent the dried raw materials from resurgence.

3. Under the action of vacuum negative pressure, the original dust in the raw materials will be filtered out through the dust filter system. Air filtration can be used to clean in reverse after each single suction to avoid the trouble caused by filter blockage.

4. At the same time, when the operator is removing dust, the motor of the injection molding machine's centralized feeding system does not stop, thus overturning the traditional barrier of stopping to remove dust; this design not only avoids the loss caused by frequent start of the fan, but also improves the production efficiency.

Disadvantages of the centralized feeding system of the injection molding machine:

1. The equipment is expensive. Since the centralized feeding system of the injection molding machine is composed of a variety of equipment, combined into a set of large injection molding production equipment, the price will be relatively high.

2. In the production process, if too many materials are put in at one time, it is difficult to change the material variety. When feeding, pay attention to the control of raw materials.

Disadvantages of centralized feeding system of injection molding machine:

1. The equipment is expensive. Since the centralized feeding system of the injection molding machine is composed of a variety of equipment, combined into a set of large injection molding production equipment, the price will be relatively high.

2. In the production process, if too many materials are put in at one time, it is difficult to change the material variety. When feeding, pay attention to the control of raw materials.

|