Under what kind of market demand is the central feeding system developed and matured? As we all know, the rapid development of plastic production automation is a kind of advanced science and technology that is widely used. Its development level and popularity are an important indicator of a country's industrial development level. Want to be invincible in the increasingly competitive market, you need a very important system that can not only reduce labor to improve product qualification rate, but also save energy and reduce production costs. This system is the central feeding system.

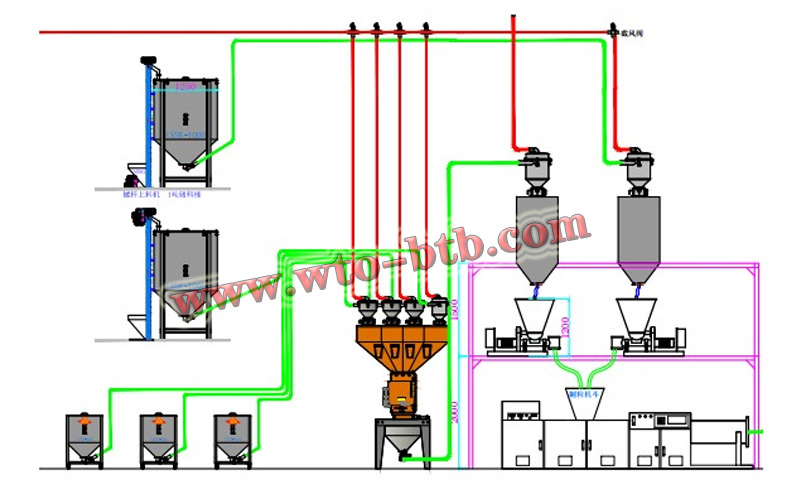

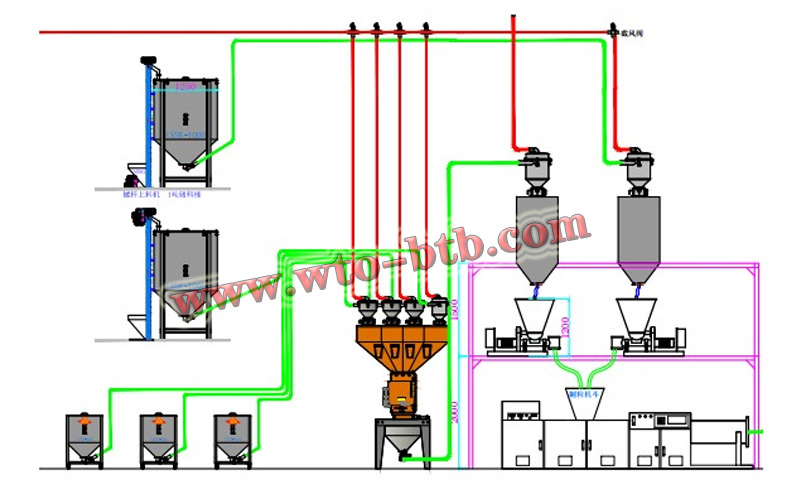

The central centralized feeding system adopts microcomputer centralized automatic control, which realizes the continuous feeding operation of pellets for 24 hours. Multiple small microcomputers respectively control the coloring process of each molding machine, the measurement is accurate, the mixing is uniform, and the color can be flexibly changed to meet the requirements of multiple colors and varieties of products. According to the production capacity of different molding machines, the feeding amount can be flexibly changed. The design of multiple feed pipes can ensure the diversified requirements of the main materials. The system has a variety of monitoring and protection functions, and the work is safe and reliable.

The central centralized feeding system is suitable for centralized feeding and control of plastic product production in the injection molding workshop, and can realize uninterrupted unmanned continuous molding operations. The system can change the variety of raw materials and the combined use of multi-color materials according to needs to realize the automation of the coloring process. The system can regenerate and use the nozzle cold material in a fully automatic way, can control all the feeding equipment,

and prevent the occurrence of blockage in the storage bin, and realize full automation by setting up a central console.

|