| Desiccant Hopper Dryer Details description |

|

| product name:Desiccant Hopper Dryer |

| release time:2020-08-28 |

| Numbering:VMD-230L |

| Brand:wtobtb |

| Price:¥Various |

| weight :450 |

| unit weight:KG |

| Producing country:CHINA |

| simple description:Fully sealed feeding system to prevent dried material from contacting open air and being re-damped.,This is a device used to dehumidifying plastic resin to achieve drying.For example,POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),LCP,PA11,

PA6.46.6,PAI,PAR,PBT,PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,

PE.HDEPE.LDPE black40%,PEEK,PE(1),

PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS,GPPS.EPS.HIPS,PSU,

PIT,PUR,PVC,SAN,SB,TPE,TPE,TPO,TPU,Dehumidifier dryerand other plastic resins must be dehumidified and dried during the production process to improve the quality of the finished product. |

| Product alias:Desiccant,Hopper Dryer,Desiccant Hopper Dryer |

|

| Desiccant Hopper Dryer Product introduction |

|

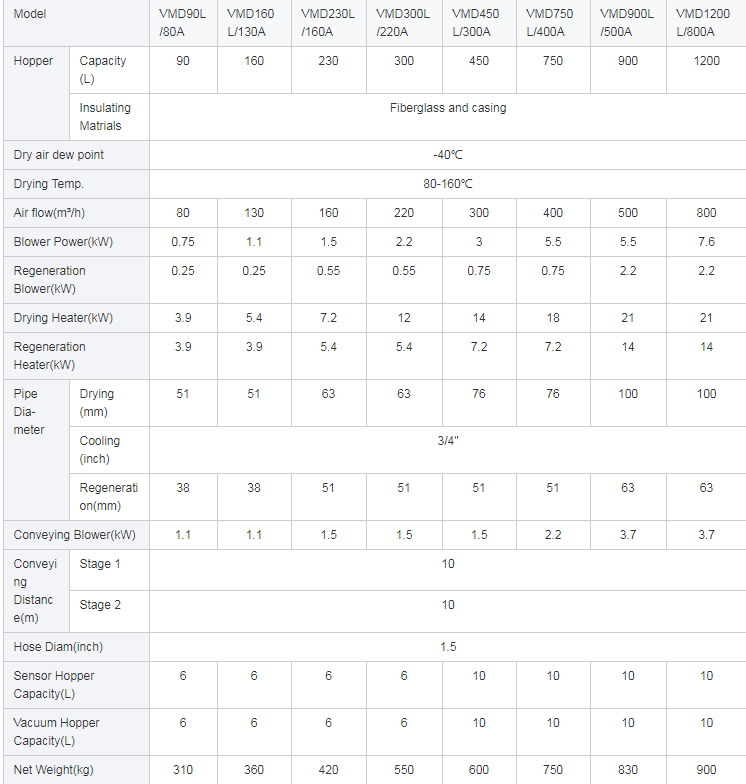

Desiccant Hopper Dryer parameter

Hopper Dryer  Product alias:Desiccant,Hopper Dryer,Desiccant Hopper Dryer

Product alias:Desiccant,Hopper Dryer,Desiccant Hopper Dryer |

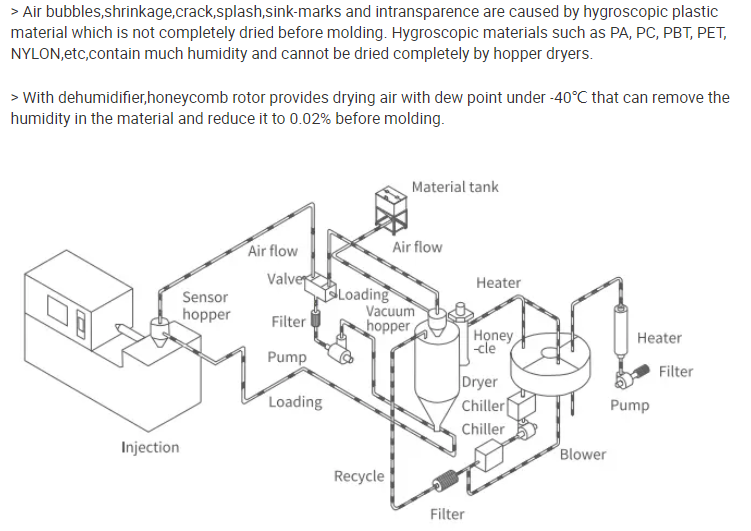

Desiccant Hopper Dryer Equipment principle

Hopper Dryer  Product alias:Desiccant,Hopper Dryer,Desiccant Hopper Dryer

Product alias:Desiccant,Hopper Dryer,Desiccant Hopper Dryer |

Desiccant Hopper Dryer application

This is a device used to dehumidifying plastic resin to achieve drying. For example,POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),

LCP,PA11,PA6.46.6,PAI,PAR,PBT,PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.LDPE black40%,PEEK,PE(1),PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,PIT,PUR,PVC,SAN,SB,TPE,TPE,TPO,TPU,Dehumidifier dryerand other plastic resins must be dehumidified and dried during the production process to improve the quality of the finished product. Hopper Dryer

Product alias:Desiccant,Hopper Dryer,Desiccant Hopper Dryer Hopper Dryer

Product alias:Desiccant,Hopper Dryer,Desiccant Hopper Dryer |

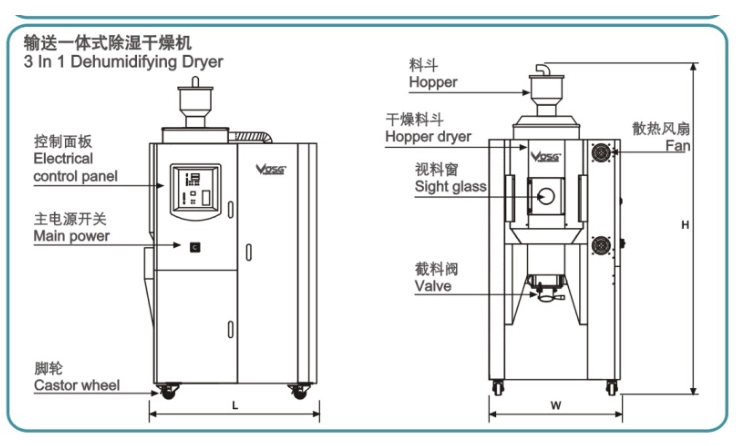

Desiccant Hopper Dryer Precautions

Hopper Dryer Features.> Integrated dehumidifying, drying and feeding into one unit.

Standard configuration is 1 to 2 feeding: 1 reed switch hopper and 1photoelectric hopper.

Optional configuration is 1 to 3 feeding: 1 reed switch hopper and 2 photoelectric hopper.

Up to 1 to 4 feeding: 1 reed switch hopper and 3 photoelectric hopper.

> Controlled by microprocessor with P. I.D. temperature control.

> Consists of LCD display and keyboard.

> Double-condenser provides lower return air temperature and dew point below -40°C (-50°C is available with chilling water).

> Easy to operate system and to understand warning messages.

> Insulating drying hopper with European standard allows better heat preservation and drying efficiency.

> Fully sealed feeding system to prevent dried material from contacting open air and being re-damped.

>Discharge valve ensures no residual materials in hopper tubes.

> Small footprint and moveable.

> PLC control with enhanced configuration is optional for feeding up to 5 molding machines.

> Dew-point monitor is optional.

Product alias:Desiccant,Hopper Dryer,Desiccant Hopper Dryer |

|

|