| Gravimetric Batch Blender for plastic molding production Details description |

|

| product name:Gravimetric Batch Blender for plastic molding production |

| release time:2020-08-17 |

| Numbering:HGB-3000 |

| Brand:wtobtb |

| Price:¥Various |

| weight :400kg |

| unit weight:SET |

manufacturer:WTO-BTB |

| patent:WTO-BTB |

| Producing country:CHINA |

| simple description:Hengju's gravimetric blender can dose up to 8 materials at accuracy ±0.5%. |

| Product alias: |

|

| Gravimetric Batch Blender for plastic molding production Product introduction |

|

Gravimetric Batch Blender for plastic molding production parameter

| Model |

3000 |

| Qty of Group number |

4 |

| Mixing capacity(kg/hr) |

3000 |

| Batch weight(kg) |

30 |

| Main material mixing range(%) |

5~100 |

| Additive mixing range(%) |

0.5~10 |

| Main hopper volume(L) |

230 |

| Additive hopper volume(L) |

230 |

| Mixing barrel volume(L) |

180 |

| Power supply(V/Hz) |

3Φ |

| 380/50 |

| Total power(kW) |

3 |

| Compressed air (kgf/cm2) |

6~8 |

| Max. noise level(dB) |

<75 |

Product alias: |

Gravimetric Batch Blender for plastic molding production Equipment principle

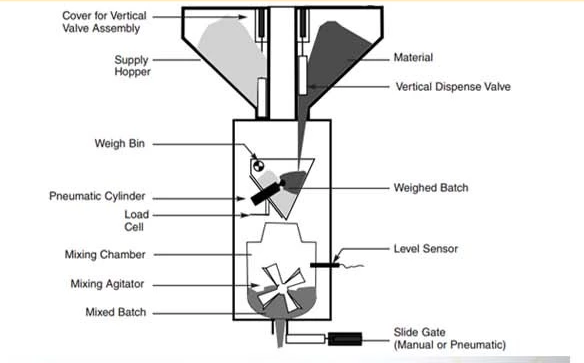

There are four kinds of raw materials 1, 2, 3, 4 in the four storage hoppers. When the blender starts to work, the pneumatic material valve of material 1 opens and material 1 falls into the weighing hopper; when the electronic scale sensor in the weighing hopper senses that the weight reaches the preset value , Material 1 pneumatic material valve closes, then material 2 valve opens, so goes for 4 cycles.

When the 4 materials fall into the weighing hopper, and the weight reaches the preset value, the valve of the weighing hopper opens, the raw materials fall into the mixing chamber, and the mixing starts, when all the raw materials in the weighing hopper fall into the mixing chamber, the weighing hopper valve closes, the mixing blade continues to mix for a while until all materials are well mixed, and then the valve of the mixing chamber opens, the mixture falls into the storage tank or the molding machine, such a work cycle is completed.

Product alias:

Product alias: |

Gravimetric Batch Blender for plastic molding production application

Gravimetric blender also called as gravimetric dosing system or gravimetric batch blender, is an industrial device used in plastic production industry to dose or weigh two or more components and then mix them together prior to processing in the molding machines. It's a high-end technology for the discontinuous blending of materials at the highest level of accuracy. After years of exploring deeply in the industry and upgrading system many times, now Hengju's gravimetric blender can dose up to 8 materials at accuracy ±0.5%. That means, for example, if your recipe is comprised of virgin 80%, masterbatch 18%, filler 2%, and if we set the batch weight as 1000g, then it means that the amount of any ingredient could be off by 5g. That's very close to Europe- made blenders and with much lower cost.

Product alias:

Product alias: |

Gravimetric Batch Blender for plastic molding production Precautions

Cautions for Operation and Maintenance Personnel

Before carrying out machine-related operations, the person who intends to operate and maintain the machine must read and understand the relevant contents of this operating manual, especially the safety-related parts.

The following safety instructions are particularly important to avoid personal injury and property damage:

1) Observe all safety and damage related information on the device.

2) Do not allow unauthorized persons to approach this device.

3) Before starting the device every time, make sure that no one is in the danger zone.

4) Please ensure that there are no tools, other equipment and objects in the workstation. Do not place tools or other objects on the device. Because vibration may cause them to fall off the device, causing personal injury and / or property damage.

5) Please keep the device and the workplace clean and tidy, and ensure that the particles are not scattered on the ground. This may cause staff to slip and be injured.

6) When cleaning or servicing the blender, wear work gloves. Work gloves will protect your hands and fingers from being broken.

7) When operating this machine, be sure to abide by the safety regulations of the local government.

Product alias: |

|

|