| Gravimetric Batch Blender Details description |

|

| product name:Gravimetric Batch Blender |

| release time:2020-08-15 |

| Numbering:HGB-2 |

| Brand:wtobtb |

| Price:¥Various |

| weight :150KG |

| unit weight:SET |

manufacturer:WTO-BTB |

| patent:WTO-BTB |

| Producing country:CHINA |

simple description:All materials are evenly mixed after being metered by gravity, and the precision can be strictly controlled.

Application range of weighing mixer:

The weighing mixer is suitable for mixing powder or granular materials in the chemical, food, pharmaceutical, feed, ceramic, metallurgical and other industries. |

| Product alias:avimetric blender manufacturer, gravimetric dosing price, gravimetric dosing manufacturer |

|

| Gravimetric Batch Blender Product introduction |

|

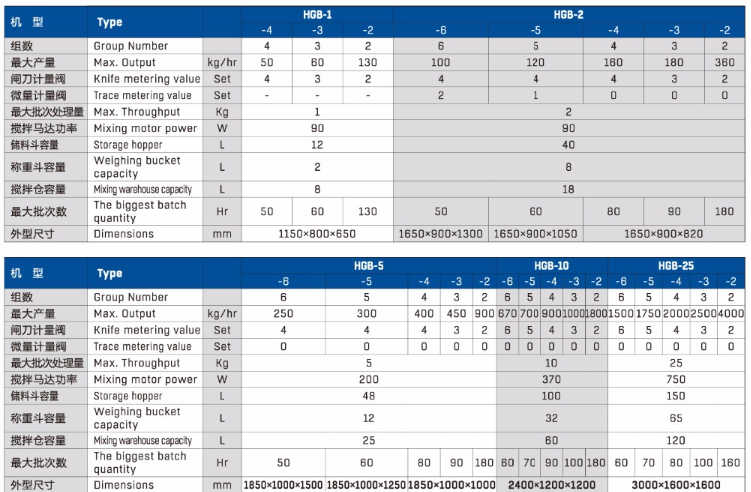

Gravimetric Batch Blender parameter

Product alias:avimetric blender manufacturer, gravimetric dosing price, gravimetric dosing manufacturer

Product alias:avimetric blender manufacturer, gravimetric dosing price, gravimetric dosing manufacturer |

Gravimetric Batch Blender Equipment principle

Application range of weighing mixer:

The weighing mixer is suitable for mixing powder or granular materials in the chemical, food, pharmaceutical, feed, ceramic, metallurgical and other industries.

Product alias:avimetric blender manufacturer, gravimetric dosing price, gravimetric dosing manufacturer |

Gravimetric Batch Blender application

Used in injection molding and extrusion industries where multiple raw materials need to be accurately mixed in proportion, and the mixing accuracy can reach up to ±0.1%. This series of products all adopt PLC controllers and use advanced batching algorithms to ensure the high quality and comprehensive technical characteristics of this series of products, so that the products have excellent performance, stable operation and safe and reliable operation.

1. Modular and detachable structure design, saving space and easy to clean;

2. It can process up to eight kinds of raw materials at the same time; the built-in suction control program can save the cost of suction control;

3. Using PLC controller to ensure stable and reliable performance and easy maintenance;

4. Adopt advanced control algorithm, independent optimization, automatic adjustment compensation and vibration prevention functions to ensure the best batching accuracy;

5. Color graphic display, touch screen operation, online switching in multiple languages;

6. Weighing, volume mixing and metering mode increase the batching capacity; with formula storage function, it can store more than 100 groups of formulas at most;

7. Hierarchical security password control and alarm history record function;

8. The controller is equipped with a standard USB2.0 interface, which can save the mixing ratio data to the U disk, which is convenient for production quality control;

9. With sound and light alarms, it is convenient for equipment personnel to quickly and accurately reach the faulty machine site.

10 All parts in contact with raw materials are made of stainless steel to prevent raw materials from being contaminated.

11. It can be directly installed on the machine or can be installed next to the machine with optional tripod.

Product alias:avimetric blender manufacturer, gravimetric dosing price, gravimetric dosing manufacturer

Product alias:avimetric blender manufacturer, gravimetric dosing price, gravimetric dosing manufacturer |

Gravimetric Batch Blender Precautions

1)All materials are evenly mixed after being metered by gravity, and the precision can be strictly controlled.

2)Advanced batching technology can accurately control and measure the ratio of each processed raw material.

3)The automatic repeat calibration function will automatically correct and adjust after each weighing to ensure the best ingredients accuracy.

4)Up to 6 kinds of raw materials can be processed at the same time

5)Modular detachable structure design, easy to clean.

Product alias:avimetric blender manufacturer, gravimetric dosing price, gravimetric dosing manufacturer |

|

|