| Plastic crusher 800 High speed Details description |

|

| product name:Plastic crusher 800 High speed |

| release time:2020-08-17 |

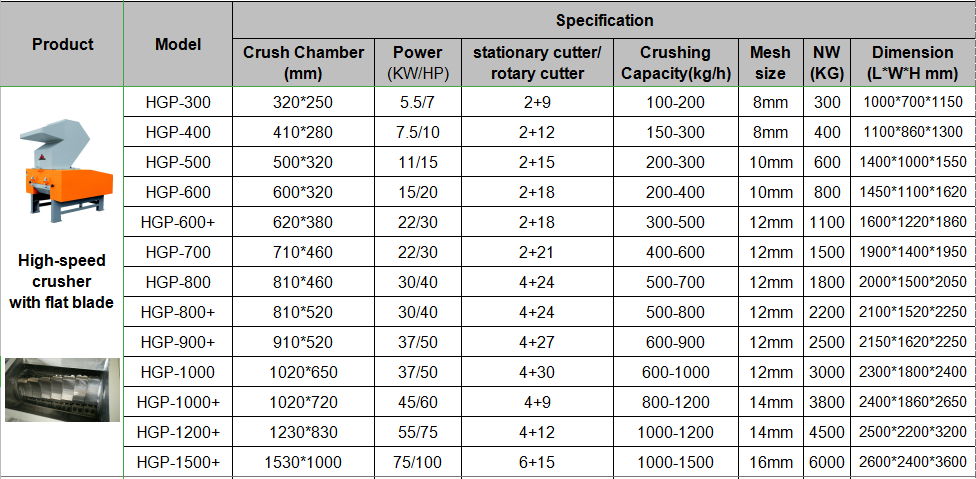

| Numbering:HGP-800 |

| Brand:wtobtb |

| Price:¥Various |

| weight :1800KG |

| unit weight:SET |

manufacturer:WTO-BTB |

| patent:WTO-BTB |

| Producing country:CHINA |

| simple description:By adjusting the blade gap, it can break the soft and hard plastic and thin film to 6-10mm particles. |

| Product alias:grinder,Crusher, automatic crusher, plastic crusher, sitting crusher,Plastic crusher |

|

| Plastic crusher 800 High speed Product introduction |

|

Plastic crusher 800 High speed parameter

Product alias:grinder,Crusher, automatic crusher, plastic crusher, sitting crusher,Plastic crusher

Product alias:grinder,Crusher, automatic crusher, plastic crusher, sitting crusher,Plastic crusher |

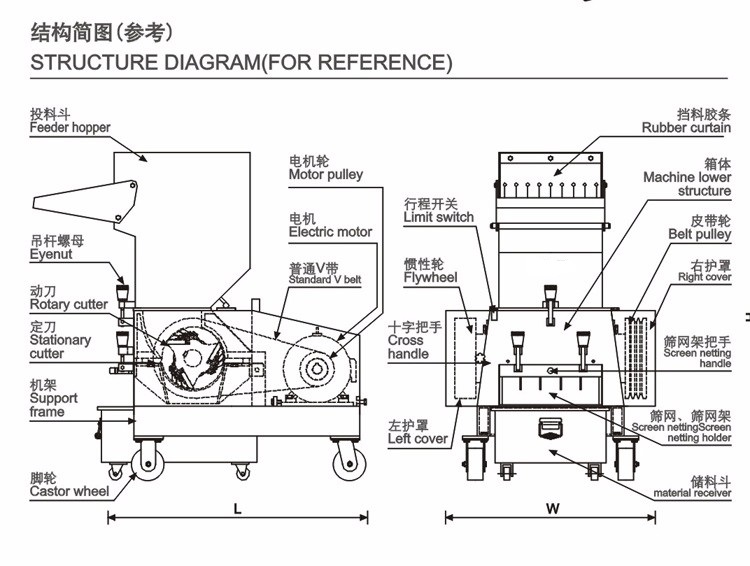

Plastic crusher 800 High speed Equipment principle

Product alias:grinder,Crusher, automatic crusher, plastic crusher, sitting crusher,Plastic crusher

Product alias:grinder,Crusher, automatic crusher, plastic crusher, sitting crusher,Plastic crusher |

Plastic crusher 800 High speed application

Product alias:grinder,Crusher, automatic crusher, plastic crusher, sitting crusher,Plastic crusher

Product alias:grinder,Crusher, automatic crusher, plastic crusher, sitting crusher,Plastic crusher |

Plastic crusher 800 High speed Precautions

Safety Instructions

1、The selection should be appropriate, avoid a large amount of plastic or too large plastic seizing-up material,once seizing-up material,should be stopped immediately,after cleaning can continue to work, the feeding should be uniform,avoid heavy load and cause damage to the machine.

2、When the blade is blunt or damaged, should be repaired or replaced in time.

3、Pay attention to the motor bearing heating, the temperature is not more than 60 degrees.

4、6 minutes before stopping, feeding is prohibited.When the material in the crushing chamber is completely broken, the machine can be shut down.

5、When plastic is difficult into the crushing chamber, do not push it by hand to avoid accidents,should stop cleaning or dredge with plastic pipe.

6、Metal parts and hard materials can’t put into crusher, so as to avoid accidents and mechanical damage.

Product alias:grinder,Crusher, automatic crusher, plastic crusher, sitting crusher,Plastic crusher |

|

|