| High-power automatic material machine Details description |

|

| product name:High-power automatic material machine |

| release time:2020-08-19 |

| Numbering:014 |

| Brand:wtobtb |

| Price:¥discuss personally |

| weight :71 |

| unit weight:kg |

manufacturer:WTO-BTB |

| patent:WTO-BTB |

| Producing country:CHINA |

| simple description:Suction machine is widely used in injection molding machine, extruder and other equipment in the raw material conveying industry, with easy installation, simple operation, long distance conveying capacity, stable production, reliable operation and operation, to achieve fully automated production of auxiliary equipment. |

| Product alias:AUTO LOADERS,automatic material machine |

|

| High-power automatic material machine Product introduction |

|

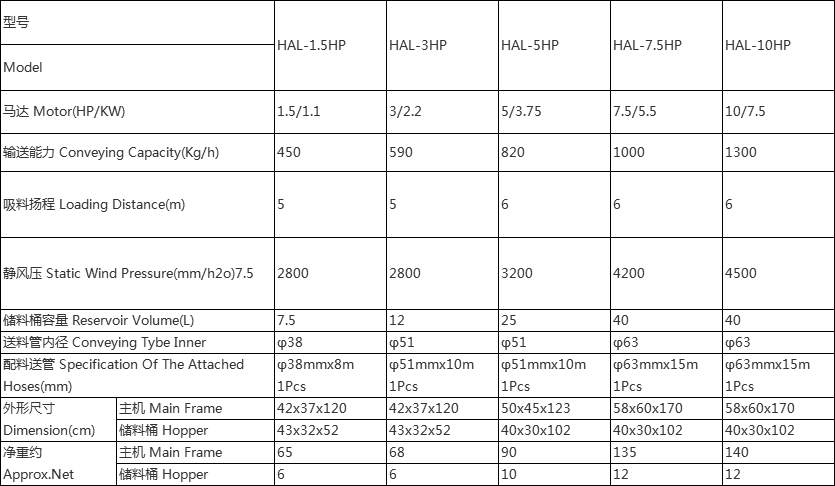

High-power automatic material machine parameter

Product alias:AUTO LOADERS,automatic material machine

Product alias:AUTO LOADERS,automatic material machine |

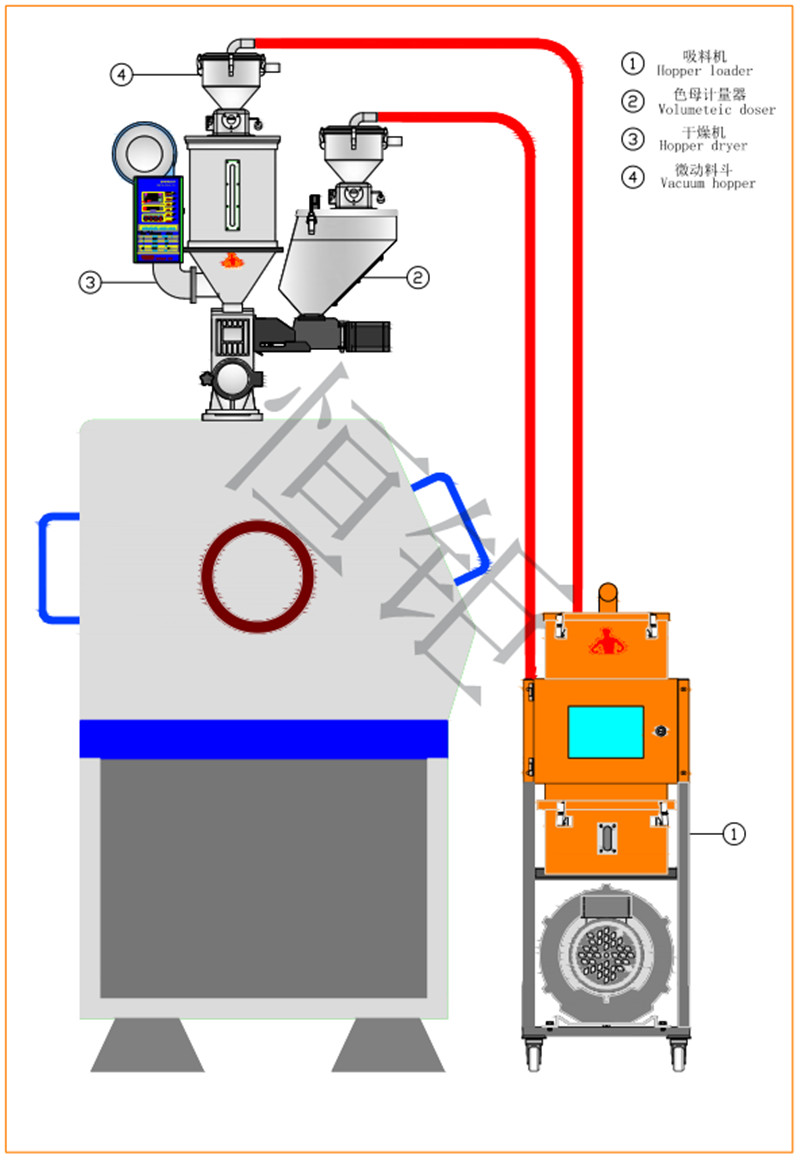

High-power automatic material machine Equipment principle

Working principle:

Vacuum suction machine mostly adopts the way of vacuum suction, the working principle of vacuum suction is to form a certain negative pressure in the hopper chamber so that the material can be sucked into the hopper.The working process of the automatic microcomputer vacuum machine as follows: when the hopper in the lack of material, contact switch signal to detect material suction machine microcomputer, microcomputer and give a

signal to the motor is up and running process of pumping air into vacuum state, when the closed system reaches a certain degree of vacuum and began to absorb, absorb into the hopper after feeding, put the preparation after the material after a certain time, and for the next cycle.When the hopper is full, the contact switch that detects the material gives a signal and the suction action terminates.In this cycle of the process so that the material can always meet the equipment material needs.

Product alias:AUTO LOADERS,automatic material machine |

High-power automatic material machine application

Features:

1. The high-power material suction machine is specially developed for the situation of large amount of material.

2. The motor power, feed pipe diameter and hopper capacity are increased in configuration to meet the demand.

3. Microcomputer control, lack of material, overload alarm.

4. Small volume, less floor space and flexible operation.

5. This series of products have passed the European CE standard certification.

Product alias:AUTO LOADERS,automatic material machine |

High-power automatic material machine Precautions

Usage and Precautions:

The separate design of main machine and hopper is safe and simple, and the independent filter device is easy to remove dust.Exhaust air: 1:3 suction mouth split type suction machine is installed, independent suction machine is installed, the independent suction machine is small in size and light in weight, can be placed directly on the dryer or other raw material containers, to complete automatic suction, the suction machine in the use of the suction mouth front part of the suction nozzle (suction gun) into the material box 20~50cm.When the material inside the material box is used up, the material suction machine cannot absorb the material when the material suction machine issued no material alarm, at this time should stop the material suction operation.When the waiting box is filled, restart the suction operation.When the material in the material box can be sucked, but the suction machine still gives an alarm, the power should be cut off immediately, check whether the motor is overloaded, remove the fault before the suction operation.The suction machine should be cleaned regularly. First, stop the operation of the suction machine, then disassemble the filter cover, take off the filter, shake the filter gently to shake off dust and dirt, and wipe it with clean cotton yarn before assembly.

During the use of the suction machine, it is necessary to check whether the suction pipe is inserted into the raw material and whether the material is stuck, whether the system is relatively sealed, whether the hopper sealing ring and filter screen sealing ring need to be replaced, whether the filter screen is blocked and whether it needs to be cleaned or replaced.

Product alias:AUTO LOADERS,automatic material machine |

|

|