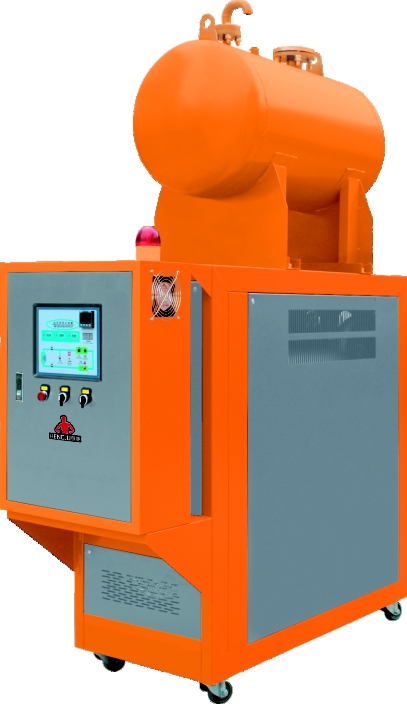

| HIGH TEMP OIL HEATER Details description |

|

| product name:HIGH TEMP OIL HEATER |

| release time:2020-08-27 |

| Numbering:019 |

| Brand:wtobtb |

| Price:¥discuss personally |

| weight :205 |

| unit weight:kg |

manufacturer:WTO-BTB |

| patent:WTO-BTB |

| Producing country:CHINA |

| simple description:It is widely used in home appliances, automobiles, communications, daily necessities and other industries, such as TV sets, computers, mobile phones, air conditioners, automotive interior accessories, headlights and optics, OA, AV instruments and other industries |

| Product alias:HIGH TEMP OIL HEATER |

|

| HIGH TEMP OIL HEATER Product introduction |

|

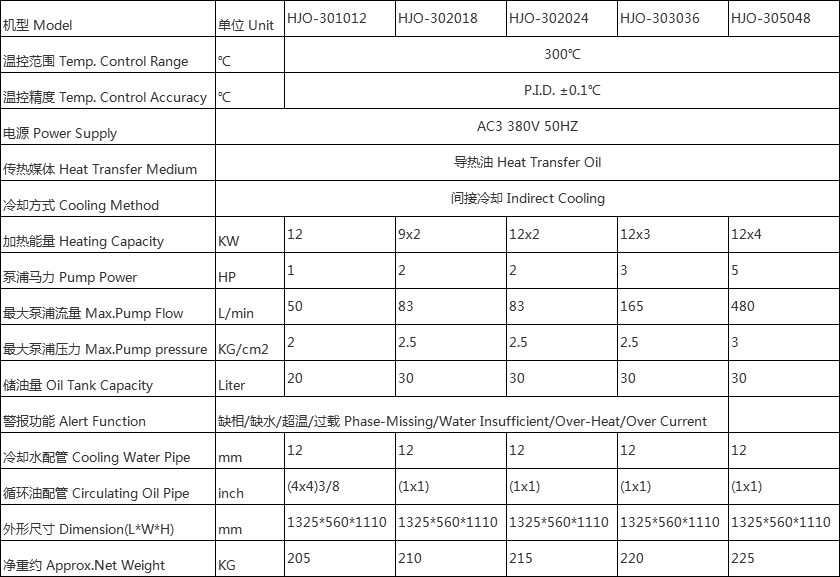

HIGH TEMP OIL HEATER parameter

Product alias:HIGH TEMP OIL HEATER

Product alias:HIGH TEMP OIL HEATER |

HIGH TEMP OIL HEATER Equipment principle

Working principle:

After the high-temperature circulating thermal oil comes out of the application equipment (mold), it enters the mold temperature machine. The equipment heats or cools the thermal oil according to the set temperature, and it is transported to the pipe entrance of the application equipment (mold) by the high-temperature oil pump, thus achieving the purpose of constant temperature control.Mold thermostats can be used for mold heating, constant temperature control, or other industrial applications where the same requirements exist.

Product alias:HIGH TEMP OIL HEATER |

HIGH TEMP OIL HEATER application

Features:

1. Explosion-proof device (optional)

2. Air return function (optional)

3. Oil return temperature display table

4. Automatic exhaust function when starting up.

5. Heating power switching function

6. Communication function to realize automatic management (optional)

7. Isolated electrical control box to extend the service life of electrical appliances

8. By-pass pressure relief loop for hot oil

9. Multi-point temperature control unit can be customized

10 Pump horsepower and heating power can be customized

11. Electric appliances adopt OMRON.FUJI. TE. LS.MOELLER.ABB.WEST.

12. Temperature control range: +45℃→300℃ for incoming water,

13. Passed CE certification

14. Stainless steel integrated pipeline reduces pipe resistance and rust

15. Control mode: imported microcomputer or PLC (optional) control

16. Complete safety protection, fault display and maintenance without professional personnel

Product alias:HIGH TEMP OIL HEATER |

HIGH TEMP OIL HEATER Precautions

Usage and Precautions:

1. Please check the cooling water circulation before use to prevent damage to the mold temperature machine due to insufficient cooling water.

We must keep the working environment of the mold temperature machine clean from dust, which can greatly extend the service life of the electrical components.

2. For new MTC, we need to make different maintenance measures according to the heat conduction medium.

If the medium is water, we must keep the water source clean, so that it is not easy to scale, and it can also prevent the pipeline from being blocked.

For oil medium, we need to replace it regularly according to the use temperature. For the temperature above 200 ℃, we need to replace it once a month or two, and below 200 ℃, we can replace it once a quarter or so, which is very good It avoids the problem that the temperature cannot be increased.

3. As for pipeline, we should judge whether the pipeline is blocked according to the connection between pump and pressure. If the pressure is too low, we can take out the heating pipe and clean it with tools, especially the filter mesh at the entrance of the system.

It is best to clean the hood once a month.

4. Regularly check the mold temperature machine water pump and oil pump for oil leakage. If necessary, the pump shaft seal can also be replaced regularly.

5. On electrical components, we can replace them in time according to the service life of the components and test them regularly to ensure safety.

Product alias:HIGH TEMP OIL HEATER |

|

|