| HIGH TEMPERATURE WATER MTC Details description |

|

| product name:HIGH TEMPERATURE WATER MTC |

| release time:2020-08-27 |

| Numbering:017 |

| Brand:wtobtb |

| Price:¥discuss personally |

| weight :76 |

| unit weight:kg |

manufacturer:WTO-BTB |

| patent:WTO-BTB |

| Producing country:CHINA |

| simple description:It is widely used in home appliances, automobiles, communications, daily necessities and other industries, such as TV sets, computers, mobile phones, air conditioners, automotive interior accessories, headlights and optics, OA, AV instruments and other industries |

| Product alias:HIGH TEMPERATURE WATER MTC |

|

| HIGH TEMPERATURE WATER MTC Product introduction |

|

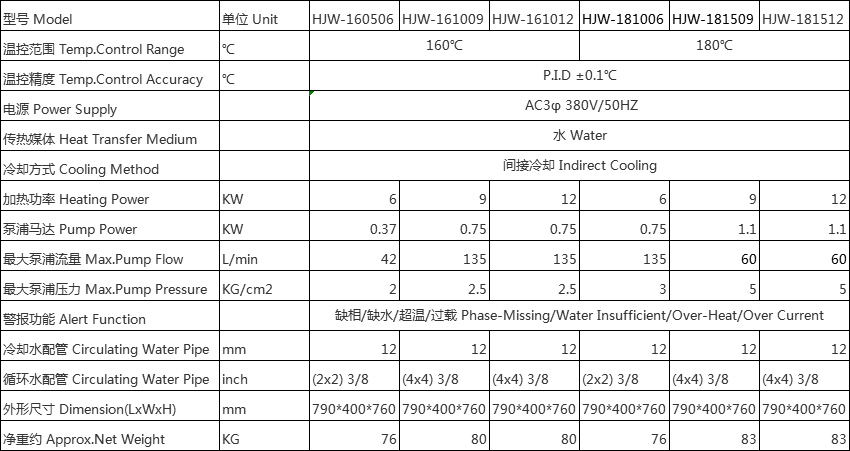

HIGH TEMPERATURE WATER MTC parameter

Product alias:HIGH TEMPERATURE WATER MTC

Product alias:HIGH TEMPERATURE WATER MTC |

HIGH TEMPERATURE WATER MTC Equipment principle

Working principle:

Water type mold temperature machine is mainly composed of circulating pump, heater, cooler, temperature sensor, temperature controller and electrical control system.Working principle: After the circulation pipe is filled with water, the water-type mold temperature machine can start to work normally.The circulating pump drives the water through the heater and cooler, into the client device, back to the circulating pump, and so on.

The temperature sensor detects the outlet temperature of the mold temperature machine. The thermostat outputs heating and cooling signals to control the operation of the heater and cooler, so as to maintain the constant temperature of water.

Product alias:HIGH TEMPERATURE WATER MTC |

HIGH TEMPERATURE WATER MTC application

Features:

1.Adopted microcomputer controller,easy to operate.P.I.D. multi-stage temperature control system can maintains an accuracy of ±0.1℃.

2.Adopted with high efficiency water cycle pump, suitable for precise mouds and the temperature requirement for mold loop with minor diameter, can achieve precise temperature controller and high efficient heat exchange.

3.Multiple safety devices including high-pressure protection,overheat protection,inlet water pressure deficit protection,safety pressure relieving,automatic water supplying,air exhausting and automatic shutdown cooling protection function.

4.Main pipes are made of uni-body 304 stainless steel.

5.Temperature control range within 180℃(Optional for magnetic pump).

6.Adopts indirect cooling method,which makes temperature controller more precise and realizes fast heat exchange.

7.Adopts magnetic pump with stable performance and no leakage

8.Water manifolds and Teflon hose as optional.

9. Sufficient safety protection and visible alarm,easy for maintenance.

10. Isolated box type electric control provides long life time service.

Product alias:HIGH TEMPERATURE WATER MTC |

HIGH TEMPERATURE WATER MTC Precautions

Usage and Precautions:

1. Please check the cooling water circulation before use to prevent damage to the mold temperature machine due to insufficient cooling water.

We must keep the working environment of the mold temperature machine clean from dust, which can greatly extend the service life of the electrical components.

2. For new MTC, we need to make different maintenance measures according to the heat conduction medium.

If the medium is water, we must keep the water source clean, so that it is not easy to scale, and it can also prevent the pipeline from being blocked.

For oil medium, we need to replace it regularly according to the use temperature. For the temperature above 200 ℃, we need to replace it once a month or two, and below 200 ℃, we can replace it once a quarter or so, which is very good It avoids the problem that the temperature cannot be increased.

3. As for pipeline, we should judge whether the pipeline is blocked according to the connection between pump and pressure. If the pressure is too low, we can take out the heating pipe and clean it with tools, especially the filter mesh at the entrance of the system.

It is best to clean the hood once a month.

4. Regularly check the mold temperature machine water pump and oil pump for oil leakage. If necessary, the pump shaft seal can also be replaced regularly.

5. On electrical components, we can replace them in time according to the service life of the components and test them regularly to ensure safety.

Product alias:HIGH TEMPERATURE WATER MTC |

|

|