| 3 in 1 dehumidifying dryer (energy saving) Details description |

|

| product name:3 in 1 dehumidifying dryer (energy saving) |

| release time:2020-08-12 |

| Numbering:001 |

| Brand:wtobtb |

| Price:¥discuss personally |

| weight :310 |

| unit weight:KG |

manufacturer:WTO-BTB |

| patent:WTO-BTB |

| Producing country:CHINA |

simple description:This machine has three functions of dehumidification, drying and two-stage feeding, and can choose a one-to-many system, widely used in all kinds of plastic raw materials, especially engineering plastics with strong hygroscopicity, such as PA, PC, PBT, PET, etc

|

| Product alias:dehumidifying dryer |

|

| 3 in 1 dehumidifying dryer (energy saving) Product introduction |

|

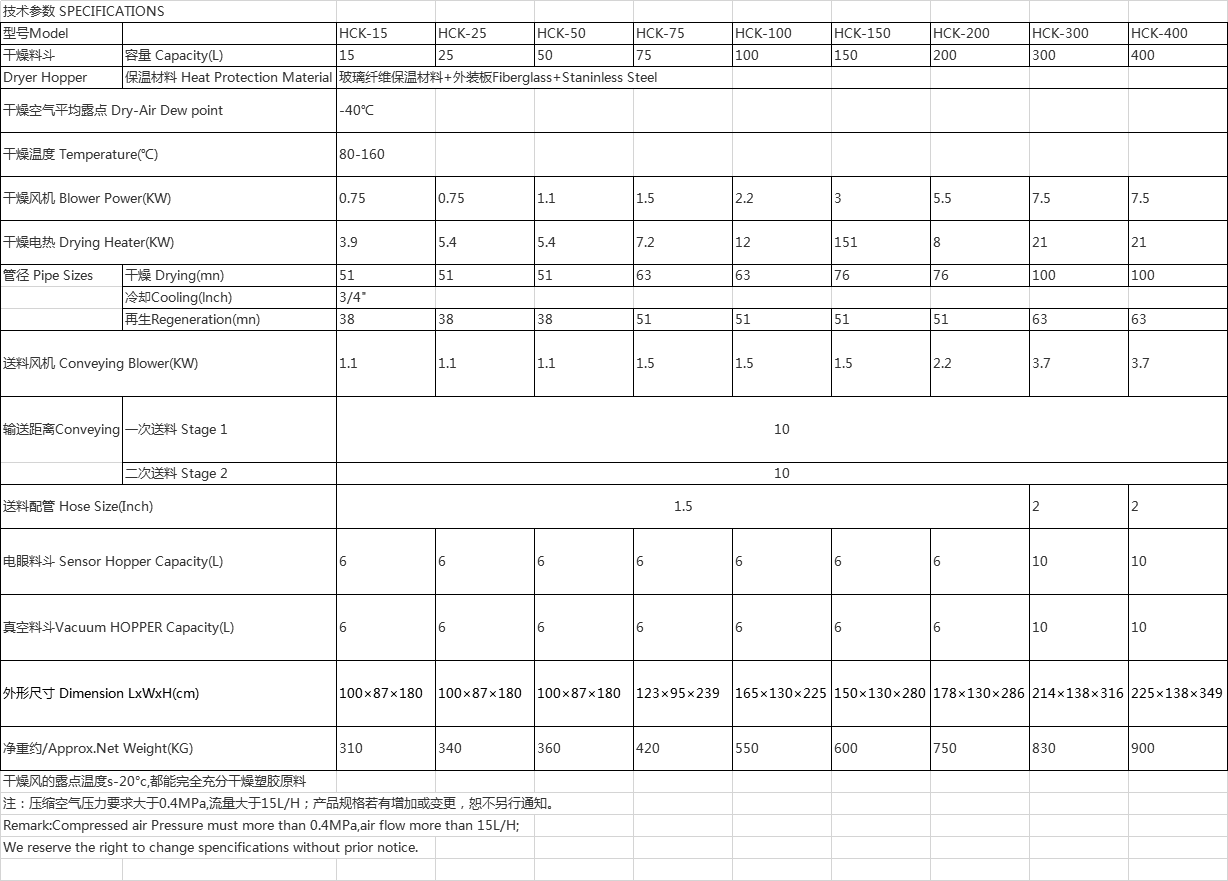

3 in 1 dehumidifying dryer (energy saving) parameter

Product alias:dehumidifying dryer

Product alias:dehumidifying dryer |

3 in 1 dehumidifying dryer (energy saving) Equipment principle

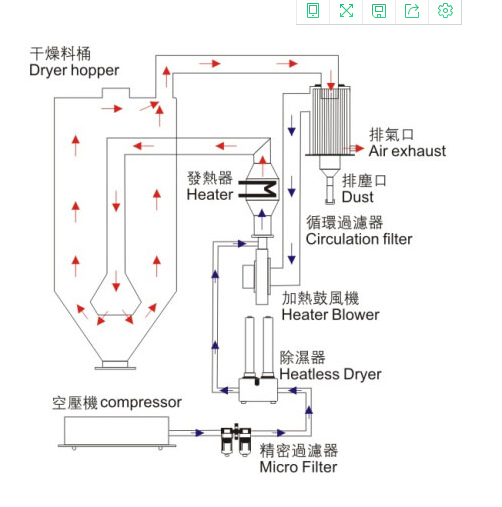

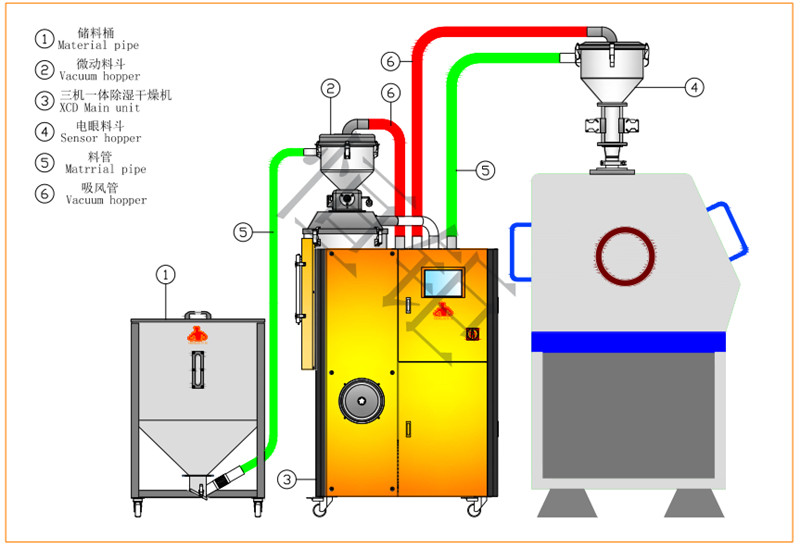

Working principle of three-machine integrated dehumidifier and dryer:

1. Dehumidification and drying part: the hot and humid air from the drying drum is cooled and blown into the honeycomb runner;The water in the air is absorbed by the wheel and then desorbed by the regenerative heated air.Two streams of air act on the wheel at the same time, and as the wheel rotates, the water in the air is continuously adsorbed and desorbed by the regenerated air and discharged, forming a stable low-dew point air.After heating to the drying temperature of plastic, it is blown into the drying drum to form a closed cycle and dry raw materials.

2. Suction part: The suction is sucked into the dry material bucket from the material storage barrel or other storage bin containers. When the vacuum hopper's magnetic spring switch detects no material, the suction motor runs to generate vacuum in the vacuum hopper.The raw materials in the storage barrel are sucked into the vacuum hopper due to the difference in air pressure. When the suction time is completed, the suction motor stops running and the raw materials will fall into the dry material barrel due to their own weight.The dried material is pumped from the drying drum to the electric eye hopper installed in the plastic forming machine.

Product alias:dehumidifying dryer |

3 in 1 dehumidifying dryer (energy saving) application

Features:

1. The integrated design ensures that the materials are dried in a completely closed system, so as to avoid the re-moisture of the dried raw materials due to contact with the air, thus achieving a good drying effect.

2. Microcomputer P.ID control system, with protection functions such as overtemperature protection, motor overload protection, motor reverse protection, shutdown delay cooling, etc.

3. Optional touch LIQUID crystal display control screen, with display working status, fault reasons and troubleshooting, machine maintenance lamp description.

4. Dry air with low dew point and dew point below -40℃ ensures that the material is fully dried.

5. Downblown drying hopper can prevent heat loss and improve drying efficiency.

6. Fully insulated drying hopper prevents heat loss and ensures stability and uniformity

7. Advanced technology, safe and reliable, superior performance, space saving.

Product alias:dehumidifying dryer |

3 in 1 dehumidifying dryer (energy saving) Precautions

Notes for machine use:

1. Please carry out electrical construction in accordance with the "Electrical Equipment benchmark", "Internal line Provisions" and the provisions of this operation manual.

2. Please do not use the power outside the specified power source.

3. Please complete the specified grounding works.(Yellow power cord)

4. Please tighten the connectors and connecting terminals of the machine body and the electric wires of the meter and meter.

5, please do not break the wire, do not put pressure on the wire, do not put heavy objects on the wire, do not clamp the wire.It could cause an electric shock.

6. Wiring and inspection shall be carried out by professional technicians.

7. When the machine needs to be disassembled due to inspection and cleaning, please cut off the power supply and compressed air source first.

8. Before line detection, the power must be cut off, and the voltage shall be measured with a multimeter 10 minutes later to ensure safety before detection.

9. Do not open the door of the control box during power supply.

10. Wet hands are not allowed to touch the machine body, control department and other accessories.

Product alias:dehumidifying dryer |

|

|