| Weighing mixing Details description |

|

| product name:Weighing mixing |

| release time:2020-09-21 |

| Numbering:021 |

| Brand:wtobtb |

| Price:¥discuss personally |

| weight :200 |

| unit weight:kg |

manufacturer:WTO-BTB |

| patent:WTO-BTB |

| Producing country:CHINA |

simple description:Purpose of weighing mixer:

The weighing mixer is suitable for plastic injection, pressing or hollow molding process, which requires a variety of raw materials to be mixed according to the weight. |

| Product alias:Weighing and mixing |

|

| Weighing mixing Product introduction |

|

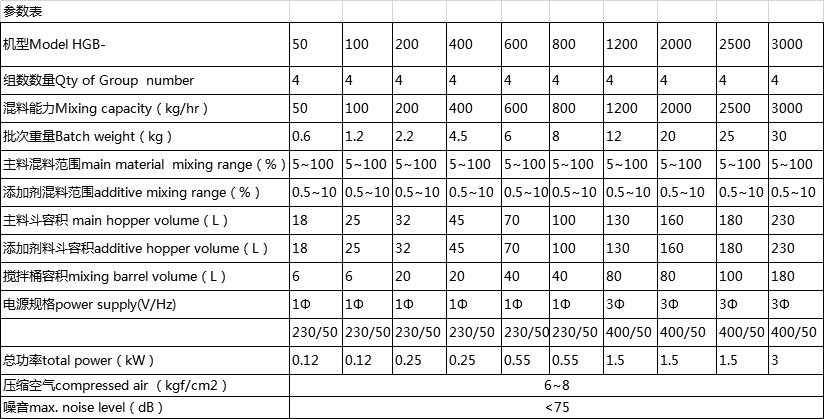

Weighing mixing parameter

Product alias:Weighing and mixing

Product alias:Weighing and mixing |

Weighing mixing Equipment principle

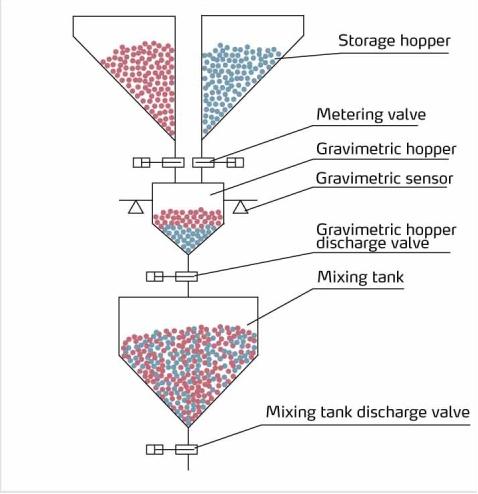

working principle :

When the machine starts to work, the metering valve of the main material bucket opens according to the set weight value and the time value calculated by the metering valve's feed quantity. The metering valve closes after the arrival of the feeding time.Check the weight of the scale.If it is

within the error range of the set feeding value, then the next number of feeding drum will be converted for measurement.This cycle until each number of barrels are finished blanking.After discharging, the weighing plate valve will be opened, and the raw materials will fall into the mixing

barrel and start the agitator to start stirring.The agitator stops stirring after the set stirring time has been reached.Manually open the baffle or automatically open the feeding valve so that the raw material of the mixing drum falls into the injection molding machine or the storage drum, and so on.

Product alias:Weighing and mixing |

Weighing mixing application

Features:

The modulized components can be disassembled for easy cleaning.

The adopted PLC panel shows reliable performance and easy maintenance.

The adopted functions such as advanced algorithm of controlling, autonomous optimization, automatic calibration and anti-vibration, can ensure the highest accuracy.

The standard models can process four dosing. (Six-dosing modules can be customized)

Touch screen operation is achieved with multiple languages option and diagrams with colors.

Up to 100recipes can be stored for later use;

The gravimetric blender is adopted with Multilevel password protection and keep alarm records;

Standard USB2.0 interface is easy for saving recipe data into flash disk, and hence fulfill the quality control management;

With sound and flash alarm, operators can be informed shortly and evidently for reparation.

All raw material contact parts are made of stainless steel, which can prevent the materials being polluted;

The gravimetric blender can be directly mounted on the injection machine or optional stand frame near the injection machine.

Product alias:Weighing and mixing |

Weighing mixing Precautions

Note for weighing mixer:

1, first plug in the power, then start the switch, the machine will start.

2. If the discharge port of the weightless mixer is not in the position you need, then it is necessary to inching until the discharge port stops at the position you need.

3. Before starting the machine, check whether the electric appliance is normal and whether the cover of the mixing cylinder is tight.

4. Clean the machine after the end of the work, especially the inside of the barrel, to prevent material residue.

5, pay attention to the reducer full lubricating oil (generally use no. 30 mechanical oil), grease in the transmission chain.

6. After use for half a year, maintenance shall be carried out, lubricating oil of reducer shall be replaced, and electrical appliances shall be checked for aging.

7, the use of a year or a little longer period of time, should be a major maintenance, check the clearance of each part of the machine, make appropriate adjustments, to keep the machine in good condition.

Product alias:Weighing and mixing |

|

|